David Chinn and Dr. Matt Seeley, Department of Exercise Sciences

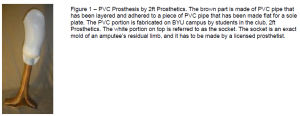

Our purpose in conducting research was to evaluate a novel, below-knee PVC prosthesis (Figure 1) relative to traditional below-knee prostheses. We aimed to collect data from the biomechanical gait analysis of amputees using the PVC prosthesis. Our desire is to help those in developing nations who have remained immobile after amputation due to lack of funds or technology in their country. This leg only costs $25.00 to manufacture, and if it is found to be similar to traditional prostheses it could help a lot of people. Since the outset of this project we have had successes and failures. Through the ups and downs I have grown in appreciation for my discipline as well as the role research plays in the process of academics. There is much more to research with the PVC prosthesis. In this report I give an account of where we are, what I have learned, and where we are going next with the research.

The design of the study involves the use of high speed video cameras that capture the motion of reflective markers that we place on bony landmarks all over the volunteer amputees. From these markers, the cameras can map their 3 dimensional locations in space, and coupled with in-ground force platforms we can use them to measure joint moments and force. These data allow us to compare the PVC prosthesis to traditional prostheses. The protocols for our study are not difficult to complete, but they depend upon an integral part, a licensed prosthetist. At this moment we are coordinating our plans with prosthetists from the area. None of the originally committed prosthetists have been able to give the amount of time that they expected. We had to adapt to a model where we include multiple prosthetists to aid us. Students in our club, 2ft Prosthetics, perform the actual manufacture of the PVC prosthesis. The part that the prosthetist has to make is the socket which is the part that molds exactly to the amputee’s residual limb. In addition to the prosthetists who have committed to help, we have gained enthusiastic support from the amputee committee. There are a lot of people in the area that want to see to it that there are affordable options for amputees in developing nations. We have had amputees wear the PVC prosthesis, and their immediate reaction is that the prosthesis feels lighter and springier than their traditional prosthesis. From their analysis, and from the direction of a prosthetist, we have taken this into consideration to now look for walking speed as a variable to see if amputees walk faster with the PVC prosthesis. With the help of many, we have conducted pilot data collection, and we are ready to begin standard data collection in the near future. The start of regular data collection was delayed from our original timeline. These delays were what made up part of the failures of the research process.

One of the most important things I have learned by being involved in this research study is that delays will happen and you should plan for them. Things went wrong like I have never seen before. Some of the delays we encountered were prosthetists withdrawing their help, high speed video camera malfunction, force platform malfunction, remodeling of the biomechanics laboratory, and a lengthy IRB renewal process through the University of Utah. All of these things have tested my resolve and character. I have especially learned that just because you are motivated to do a project and have the vision of how it can impact the world does not mean that everyone else will catch that vision when they talk to you. The prosthetists I have worked with, though interested, have lagged far behind my motivation levels. I had to be a driver, and I continue to drive this project with all that I have. I set out to learn about the application of biomechanics as they pertain to prosthetics testing. I am learning the biomechanics, but I have been inspired by all the other disciplines I have had to learn in order to keep the project rolling. I have had to learn how to use good business and sales techniques in order to build value and help prosthetists see the benefit of being involved in our study, I have had to learn some programming in order to use some of the computer programs that allow us to analyze the joint moment data, and I have learned a tremendous amount about prosthetics. In addition to the things I am learning, a very valuable part of my experience has been the contacts I have gained in the prosthetics community. I have collaborated with prosthetists from El Salvador, Massachusetts, Nevada, and all over Utah. I have also received guidance for adapting research protocols from a man who is starting a prosthetics technical school out of Baylor College of Medicine in Texas. All of these things have added to my experience at BYU, and it will be looked at as one of the richest experiences I have gained here.

There is much more to be done with this project. The delays have set us back, but they have not taken the wind out of our sails. We still care about helping people in developing nations as we did before we began this project. Now that we have secured some new help, we aim to complete data collection by the end of Winter semester, 2013. Once we finish data collection we will be able to perform a statistical analysis of the data. At the completion of data analysis we will submit our findings for publication. Through networking we have found prosthetists who want to take us with them to developing nations this summer to give out a prosthesis made by the Red Cross, and, if viable, we will teach people to fabricate the affordable PVC prosthesis.