David Schlesinger and Dr. Alan R. Harker, Microbiology

Trichloroethylene (better known as TCE) has been used for decades as a solvent for fats, waxes, oils, paints, varnishes, and rubber. This characteristic of TCE has made it useful in industry for cleaning and degreasing; hence, its wide use at airports, and military installations.

Along with these practical applications TCE is toxic to humans. According to the National Cancer Institute, TCE is a proven carcinogen. When in the environment, TCE can get trapped in the soil and can also pollute groundwater. In North America alone there are over 90,000 sites that are contaminated with TCE, which pose a potential health threat, wide in scope and geography.

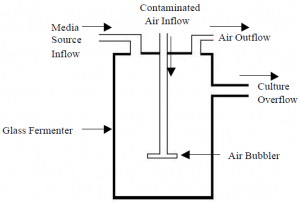

My project consisted of constructing a bench scale bioreactor to eliminate TCE from contaminated groundwater. The main component of my bioreactor was a strain of bacteria called Ralstonia eutropha (formerly Alcaligenes eutrophus) AEK301/pYK3021. This particular strain has been solely engineered to degrade TCE. This bacterium was grown up in a 1.5L glass fermenter (as shown in the diagram below) in a complex media supplemented with sodium citrate (which has been shown in previous experiments to increase TCE degradation).

In a separate container about 100ml of industrial grade TCE was overlaid with 500ml of water, creating two phases (due to their different densities). The TCE was airstripped from the TCEsaturated aqueous layer and allowed to bubble through the bioreactor. As the TCE saturated air moved through the bioreactor, the TCE was taken up by the bacteria and degraded. The air leaving the bioreactor was fed through a container of activated charcoal to trap any residual TCE that wasn’t degraded by the bacteria. To maintain a steady growth phase of bacteria, fresh media was constantly fed into the bioreactor and any excess (used) media was allowed to pour out through the overflow nozzle.

Once the bioreactor was tested for leaks and was running properly, TCE degradation was tested using a gas chromatograph. At given time intervals samples of air were extracted from the top of the bioreactor and fed into a Hewlett Packard gas chromatograph.

Once it was determined that the bioreactor was successfully degrading the TCE, the next step was to modify conditions so as to optimize TCE degradation. This is the current standing of my project. I am in the process now of finding the optimal temperature, pH, TCE concentration, sodium citrate concentration, airflow rate, and fresh media flow rate. Preliminary results have shown that TCE degradation is optimal (up to 90%) at a sodium citrate concentration ranging between 10mM and 20mM. I am currently testing the other parameters. I still have many conditions to test to try and achieve full degradation.

In conclusion this bioreactor I created seems to be successful in degrading TCE. The next step, after optimal conditions for TCE degradation have been determined, would be to test this bioreactor on a much larger field scale.