David M. Macdonald and Dr. Harrison Powley, School of Music

The Ancient Hydraulis

The ancient hydraulis is the earliest precursor to the modern pipe organ and the first keyboard instrument. The word hydraulis comes from the Greek words for water (hydro) and pipe or chamber (aulos). The hydraulis was invented in the 3rd century B.C. by Ctesibius, an engineer from Alexandria, Egypt. A hydraulis creates pressurized air using the weight of water. The pressurized air is delivered by a key mechanism to pipes which create an audible sound.

How it Works

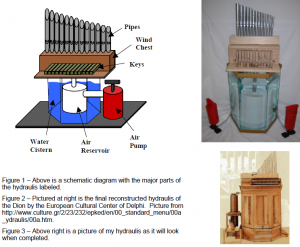

A hydraulis is an aerophone, an instrument that utilizes standing air waves. First, air is pumped into the air reservoir using a hand pump. This air is held at a constant pressure by the weight of water that it displaces. The pressurized air is piped into a wind chest where keys direct the air to pipes of varying lengths. When the pressurized air enters a pipe it creates a standing wave inside the pipe. Vibrations created by this standing wave are heard as an audible pitch, due to the length and size of the pipe. Each pipe sounds only one pitch at a fixed volume unless there is a change in the air pressure (Fig. 1).

Recent Discovery

In 1992, archeologists from the University of Thessaloniki uncovered the remains of a 1st century B.C. hydraulis at the Greek city of Dion (at the foot of Mount Olympus). In 1999 the European Cultural Centre of Delphi finished a four year project of reconstructing a hydraulis using the uncovered remains and documented descriptions as evidence (Fig. 2).

Modern Church Organ

The hydraulis has evolved over many centuries to become the modern church organ of today. The first modification of the hydraulis was to replace the water regulated pressure system with a weighted bellows. A weighted bellows is like a large leather sack with weights on top so that the air inside maintains a constant pressure. This pneumatic system was advantageous to the hydraulis because it was easier to make and maintain. This change is recorded as early as A.D. 100 and organs were almost entirely of this type by the 5th and 6th century. After this time the organ underwent a major expansion and found a permanent home in churches of the West by the 9th century.

Building a Working Model

When I first learned about the ancient hydraulis I thought it would be neat to make one. I understood the principles of how it operated but knew little else about how to build one. After researching as much as I could about the hydraulis, I decided to experiment and see if my idea for making one would work. First I made a monometer, a device that would measure the air pressure needed to make the pipes sound. I found that I could easily obtain four or five inches of pressure which is common for modern organ pipes. Next I began looking for pipes and spent some time searching for pipes of the right size. I made a small test model with only one pipe fed directly from the air reservoir. It seemed to work fine but I still didn’t have the pipes I needed. I continued to search for pipes until I finally purchased some on eBay.

When I knew what size pipes I would be using I bought wood and rented a saw from Home Depot to begin building. All the work so far has been done in the basement of the Wells Hall dormitory. Some of the difficulty in completing the project has been the limited tools and lack of a wood shop. I had to be creative in designing the hydraulis to be functional and historical but also so that I could complete the work with the tools and materials that were available to me. In creating the design I talked to M.L. Bigelow and Co., organ builders of American Fork, Utah.

They showed me a modern key mechanism which I modified and used, along with modern organ pipes which are not true to the original hydraulis but serve the purpose of my model. My purpose in creating a hydraulis was to show how the ancient hydraulis worked rather than to make a perfect historical replica. I have succeeded in doing so by using glass and Plexiglas to make the inner parts of the organ visible as well as the hydraulic air pressure system. My model is not fully completed. I am currently in the process of finishing the wood and assembling the various parts. I am planning that the finished model will be on display at Brigham Young University campus beginning winter semester 2004 (Fig. 3).