Michael Clemens and Dr. Robert Davis, Physics and Astronomy

The Atomic Force Microscope (AFM) is a powerful instrument that has many applications in various fields of scientific research. It has the ability to image surfaces without requiring a high vacuum and has the ability to image samples that are in a fluid. It also is able to image surfaces without damaging them, and doesn’t require as much time in sample preparation. It has the resolution capability on the order of tens of nanometers (nm), which is one millionth of a meter. These qualities make the AFM very useful in doing scientific research.

While the AFM has the ability to image very small features, it has a limit to its resolution capabilities due to the size of the tip. The average silicon AFM tip that can be purchased has a radius of curvature of about 5-10 nm. So the smallest feature that a tip of this size can image is 5-10 nm. Making the tip any smaller causes it to be very brittle, and is not possible to do repeatedly.

Carbon Nanotubes were discovered over a decade ago and have been found to have many intriguing properties, among which is their size and strength. Single-Walled Carbon Nanotubes (SWNT) can have a radius of less than a nanometer and are about 1000 times stronger than steel of that size. The idea of attaching a SWNT to the end of an AFM tip in order to increase its resolution capabilities was thought of years ago, however a successful method of rigidly attaching them that can be used in mass production has yet to be devised.

A method was devised by BYU graduate student Jed Whittaker and Dr. Robert Davis of rigidly attaching a SWNT to an AFM tip. The first part of this process was to grow or synthesize a SWNT on the AFM tip using a Chemical Vapor Deposition (CVD) method. I was chosen to devise a way to do so by experimentally finding out what temperature and what gases would give the optimum growth.

In order to do this research I needed to be trained in proper use and disposal of chemicals and how to operate use the furnace. I also needed training in operating the Scanning Electron Microscope (SEM) in order to image the SWNTs that I would grow. This required me to take InBio 580, a three credit hour class that teaches how to use the SEM. There was a lot of training that was required before I could really start on the project itself.

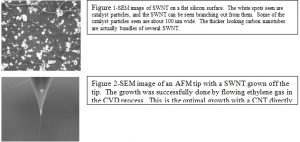

I was trained in growing SWNT by using a recipe that had been devised already to grow SWNTs on a flat silicon surface. A catalyst made of Molybdenum and Iron had been created by a previous student had proved to be efficient in growing a good number, but not too many, SWNTs on a flat surface when treated with methane gas at high temperatures (figure 1). However, I found that when I tried using the recipe on an AFM tip, which is made out of silicon as well, no SWNTs grew off the tip of the AFM.

I tried several different ways of growing with the methane, but none worked at all. So I tried using a different gas to get the growth that I wanted. I chose to use ethylene gas and was quite successful. After experimentally determining the optimum growth time and temperature, I was able to repeat my results many times. On average, about 50% of the AFM tips are successful in having a SWNT off the tip. (Figure 2)

It was apparent that a way to recycle tips that were unsuccessful would be needed if I couldn’t get more that a 50% success rate, so I found a way. I found that by flowing water vapor across the surface at high temperatures cleaned the silicon of the SWNT, but not the catalyst, so they could be reused for growth as many times as needed.

In the future, we will work on shortening the SWNTs that are successfully grown off the AFM tips and also work on rigidly attaching them to the surface so that they become usable and marketable. This method will allow us to eventually manufacture the AFM tips with SWNTs in a mass production so that they could be created and sold.