Michael M. Choi and Dr. Larry Baxter, Chemical Engineering

Black liquor is a recycled byproduct formed during the pulping of wood in the papermaking industry. In this process, cellulose is used to form paper fibers while lignin is combined with water and chemical used for the extraction to form black liquor. Black liquor is burned in a recovery boiler to produce steam and electricity and is the second largest renewable energy next to hydro energy.

During the last two years, a comprehensive, three-dimensional model of a fixed bed has been developed. Finite-volume equations estimate pressure drop through porous media with the Ergun equation, a semi-empirical equation based on Darcy’s law, to predict fluid flow. Gas and particle temperatures are calculated using established empirical heat transfer correlations together with heat released/absorbed by chemical reactions. The model also predicts air flow, including penetration depth into the bed, heat transfer between the bed and surrounding gases, and species concentrations and reaction rates. The existing model was be modified to predict these same characteristics for a black liquor char bed.

The bed was divided into discrete volumes. The temperature, composition, flow, and reaction rate at each node were calculated using a finite volume method. A generalized equation describing energy, mass and momentum transport appears below.

![]()

The first term in the equation represents the accumulation of the property φ over time. The second term describes convective transport. The third term signifies the diffusive transport and the last term represents generation or destruction of the property φ. The above equation was simplified to series of algebraic expressions and was solved numerically for each node. The Thomas algorithm was used to solve these sets of equations.

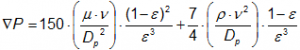

The model uses the Ergun equation, a semi-empirical correlation based upon Darcy’s law, to predict the flow pattern within the bed. This approach was used since shear forces of the gas do not affect the flow pattern as much as the wall boundary layer forces in a porous media. Therefore, Navier-Stokes-style equations were not used. The Ergun equation is shown below.

The model includes global kinetics for char oxidation and char gasification by water and carbon dioxide. Gasification reactions were modeled using several published kinetics. Gas phase reactions include carbon monoxide conversion and volatiles combustion. In the future, the pyrolysis, evaporation and melting of inorganic material will be incorporated as submodels.

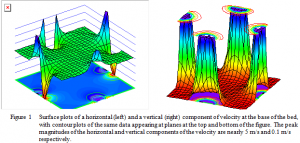

Figure 1 is a surface plot of a horizontal component of velocity at the base of the black liquor char bed. The bed was assumed to be 3.7 m in width and depth and 1.4 m in height. Air jets were assumed to hit the side of the bed in four symmetric directions. The region where the horizontal components of velocity are zero is approximately in the middle of the left Figure. The fluid flow in the regions other than where the air jets hit the bed directly is minimal. Therefore, it can be concluded that the great majority of the base of the bed is minimally impacted by the impinging jets on the side. In addition, the center of the base of the bed experiences a minimal pressure gradient, therefore is relatively stagnant.

A summary of this work has been published at the International Chemical Recovery Division Conference that was held on June 2004, at Charleston, South Carolina. Other information about the model and the results can be obtained from the published paper .

In addition to this computer code, another computer program was written using Visual C++ and OpenGL. This program allows the user to modify the bed and the computational settings and displays the model predictions in three-dimensions. Instead of using another commercial visualization package to display the predictions, this new visualization program allows the user to visualize the data in many multiple ways that are more fitting for the model.