Michael Johnson and Dr. Scott Bergeson, Physics and Astronomy

Cell phones, computers, and other electronics seem to get smaller while their speed and efficiency seem to increase—proving that bigger is not better in this realm. One of the main technologies that has been driving these improvements is lithography, the process by which light is used to etch out the component features on the microchips. Improvements in lithography techniques lead to smaller and faster chips. One of the current ideas to improve lithography is to use x-rays, which have a smaller wavelength and will print smaller features. My research is focused on calibrating a spectrometer that will monitor x-ray sources that could be used in applications like lithography.

Spectrometers are devices that spread out light so that the different wavelengths are distinguishable, much like how a prism spreads out sunlight so that you can see the colors of the rainbow. When dealing with lithography, it is very important to know what wavelengths are being emitted, so it would be beneficial to have a spectrometer that can characterize the output from the x-ray source. My goal is to calibrate a spectrometer that can give the absolute intensity of each wavelength produced by the source—which is essential for lithography and other applications.

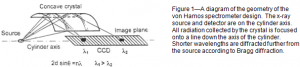

The von Hamos design for a spectrometer is advantageous because of its focusing scheme. The spectrometer is a cylindrically bent crystal with the x-ray source and the detector on its axis (Figure 1). Thus, any x-rays coming from the source refract off the crystal and are focused onto a single line. The wavelengths are spread out according to Bragg diffraction: nλ=2d sinθ, where n is the diffraction order, λ is the wavelength, d is the crystal lattice spacing, and θ is the angle of refraction.

We used a CCD linear array as the detector and a curved sheet of mica as the crystal with a 2d spacing of 19.88 angstroms. Our x-ray source was a laser-produced plasma created by focusing a high intensity laser (250 mJ) onto a solid target. For the calibration we used magnesium for a target, which rotated on a screw so that we could take several readings without realigning the devices.

To make proper readings, the spectrometer has to be precisely aligned with the source and detector both on the axis of the cylinder. To do this alignment, the laser was fired with the CCD exposed. The output from the CCD was displayed on a computer for each shot of the laser. There was a diffraction pattern on the CCD from the visible light, and the position of the spectrometer could be adjusted to maximize this pattern, which indicated proper alignment. At this point, the CCD was covered with an aluminum filter so that only x-rays would be detected.

The calibration of the spectrometer was performed using a previously calibrated PIN diode, which was also covered with the same aluminum filter. A magnesium target was chosen because only a narrow band of x-rays would get through the aluminum filter. Thus, all of the emitted x-rays picked up by the diode would also be read by the spectrometer. We took a reading from both the diode and the spectrometer for the same laser shot. The diode allowed us to determine the intensity of the radiation from the source, and then we could determine the intensity per count from the CCD.

The wavelength scale was determined using two known characteristic wavelengths emitted from the magnesium target. By associating the CCD pixel numbers with the known wavelengths, we determined a relation for all wavelengths collected by the detector in that position. With the spectrometer calibrated in this way, other materials could be used as the target, and the spectrometer would determine the intensity and wavelength of the x-rays emitted (Figure 2).

This work was presented at several conferences—DAMOP, SPIE, and the Four Corners Research Conference, and has been published in the SPIE proceedings. Currently, we are expanding the project by using a conically bent crystal. This will allow the spectrometer to be placed further from the source.

This project has been beneficial to my education, giving me material for my senior capstone project. It has also made a wider contribution by increasing our ability to monitor x-ray emissions for applications such as lithography. We have demonstrated that the simple design of this spectrometer and relative ease of alignment and calibration make it an effective tool.