Tenli Waters and Dr. Spencer Guthrie, Department of Civil and Environmental Engineering

The purpose of this report is to give the results of research conducted to measure the extent of internal curing occurring in the field in concrete bridge decks constructed using lightweight concrete compared to conventional concrete. With permission from bridge engineers at the Utah Department of Transportation and in cooperation with personnel at Provo River Constructors and Raba Kistner Infrastructure, Inc., we used sensors donated by Decagon Devices to monitor moisture content, temperature, and electrical conductivity in four bridge decks located in Utah County along the I-15 corridor: 400 South, 400 North, 800 North, and Geneva Road. The bridge decks at 800 North and Geneva Road were constructed using lightweight concrete, while the bridge decks at 400 South and 400 North were constructed using conventional concrete.

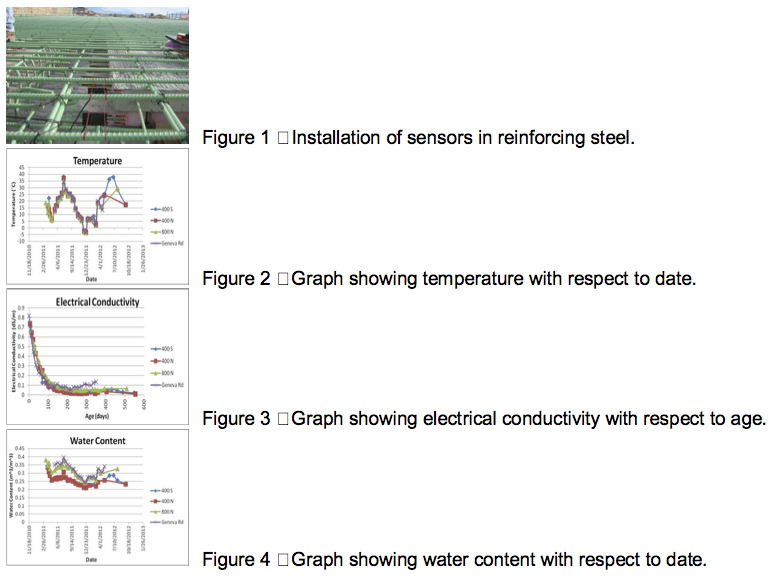

At each bridge, two sensors were installed at the level of the top mat of reinforcing steel in the right wheel path of the right lane of northbound traffic (See Figure 1). The sensor cables were routed out of the deck through the east wing wall of the bridge where measurements could be safely and conveniently obtained. We took measurements from the sensors at each bridge deck every two weeks until the bridge deck was one year old, after which measurements were taken on a monthly basis. There were a few instances where we were not able to record measurements from the sensors due to further construction at the bridge decks, blocking access to the sensors.

Unfortunately, both of the sensors at the Geneva Road bridge deck and one of the sensors at the 400 North bridge deck were damaged and stopped giving readings after May 1st, 2012, and both of the sensors at the 800 North bridge deck were damaged and stopped giving readings after July 31st, 2012. After contacting Decagon Devices, we believe that these failures are due to deterioration of the potting material in the sensors.

Lightweight concrete uses expanded shale aggregate instead of limestone aggregate used in conventional concrete. Expanded shale aggregate absorbs about 10 times more water than conventional aggregate. For lightweight concrete bridge construction, the smaller particles of the shale aggregate (fines) are soaked in water before construction. The extra water contained in the fines is used to prolong the curing phase of the concrete and increase hydration of the cement. The extended curing is called “internal curing” because the water used to extend the curing comes from inside the fine aggregates. Full curing and increased hydration lead to greater strength in the concrete and may provide greater resistance to chloride ingress.

Resistance to chloride ingress is desirable because corrosion of reinforcing steel in bridge decks is caused by the diffusion of chloride ions from deicing salts into the concrete. When the reinforcing steel corrodes, rusting occurs; rust expands to 5-7 times the size of the original steel, causing the concrete to delaminate and crack, leading to failure of the bridge deck.

The temperature of the deck does not directly affect internal curing; however, we wanted to be sure that lightweight and conventional concrete are comparable in this area. Figure 2 graphs the temperature data (averaging the values from the two sensors) from each bridge deck according to the date the values were retrieved. We can see that there are no major differences in temperature between lightweight and conventional concrete.

According to the American Society for Testing and Materials (ASTM) test C1760-12, electrical conductivity has a theoretical relationship to the diffusion coefficient of chloride ions, in the concrete. Higher electrical conductivity indicates a higher possibility that the rebar can become corroded. Electrical conductivity is measured by our sensors in units of decisiemens per meter of rebar (ASTM, 2012). Our data shows that electrical conductivity is similar between lightweight and conventional concrete bridge decks when graphed according to age (See Figure 3).

Moisture content in the bridge deck is the most important factor in determining whether or not internal curing has occurred. Higher water content after a longer period of time implies that internal curing is occurring, and means that the concrete is able to continue to gain strength. Water content was measured in units of meters3 of water per meters3 of concrete. Figure 4 graphs the water content. The average water contents in the lightweight concrete bridge decks are about 20% higher than those in the conventional concrete bridge decks. This means that internal curing has definitely occurred and the pre-soaked lightweight fine aggregates were able to hydrate the cement more fully.

Reference

American Society for Testing and Materials (2012). “ASTM C1760 – 12” ASTM C1760 – 12 Standard Test Method for Bulk Electrical Conductivity of Hardened Concrete, <http://www.astm.org/Standards/C1760.htm> (November 13, 2012)