Jacey C. Morine and Dr. Aaron Hawkins, Electrical and Computer Engineering

Cancer cell research is an exciting field of study that has involved a variety of disciplines. In my area of research, I was involved on the electrical engineering side of cancer cell research. We used a small scanning probe that was able to image small objects based on the changes in measured voltage. Eventually, we should be able to image individual cells as we make these tips smaller and smaller.

Many problems arise as the scanning tips are made smaller and smaller. This is why we had to first build large tips that were easier to work with. When I started the research project last summer, we had begun making tips that were about 100 microns in size (Fig. 1). These were built by threading a copper wire through a small syringe. Once we optimized the resolution of the 100 micron tip, I made the first few 30 micron tips (Fig. 2). This was accomplished by threading a smaller copper wire through a stainless steel tube (instead of the syringe) in which the tube itself was only 100 microns in diameter. Threading a tiny wire through such a small hole is much easier said than done. One of the problems with the smaller 30 micron tip was that over time it seemed to oxidize, or rust, because it was in an aqueous solution. Consequently, we had to sand the tip periodically so that is was free of impurities. Previously, our research team was able to measure larger samples like a flower petal. It was not until I made the 30 micron tip that we were able to image what we hypothesized to be clusters of individual cells.

After we pushed the limits of the 30 micron tips, I began to build and test the 8 micron tips during the fall and winter. We were getting very close to the size of tips necessary to image cells. These tips took more time to make and to perfect, since the wire was much thinner. Although there were disadvantages to using smaller wire, one advantage was that we didn’t experience any of the problems with the oxidation since the 8 micron wire was made out of tungsten instead of copper.

The 8 micron tips that I made showed resolution that was comparable to the 30 micron tip, yet it didn’t seem to be any better, and in fact it seemed to put out a weaker signal. This could not be explained, so we used a different measuring setup for our tips. Soon after we constructed our new setup, one of our crucial pieces of equipment that we were using broke down so we had to use a different measuring system. I helped to construct a test device to check our theory of how the micro tip worked against what we actually measured in the lab with this new setup. This was particularly crucial since we had to accurately predict how the resolution would improve as we made the tips smaller. Second, we had to understand how our tips worked so we could solve any problems when they came up. Third, we had to know what we were talking about when we submitted our results to be peer- reviewed and published.

So, we simulated our tip by constructing a device with the characteristics we thought the scanning tips should have. By using many complicated equations, I saw firsthand how electrical engineers can apply their skills to analyze real world problems. I applied some of my own skills by building a tuned circuit. It was a valuable opportunity to actually use the tools I had acquired through my education. Eventually, we were able to match our predictions to our actual measured data.

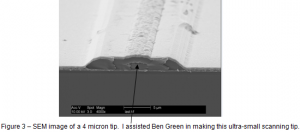

In addition to making the 8 micron tips, I had the opportunity to assist in building 4 micron tips. Ben Green, a fellow undergraduate student, specialized in the microfabrication of these tips in the BYU cleanroom (Fig. 3). Over the summer, he taught me the process steps and the many pitfalls that can occur during the sensitive fabrication process of these tiny devices.

Although we still were not been able to image individual cells with the smaller 8 and 4 micron tips, I know I have laid a strong foundation for future research in this area of study. With our new measuring setup we are better prepared for the problems that will arise when we use very small scanning tips. Learning how to build tips in the cleanroom was the crowning achievement of my experience at BYU and in making tips that will in some way aid in cancer cell research