Suman Pokharel and Dr Matthew Jones, Department of Mechanical Engineering

Each day more than 2 billion people cook using open fires or fires in primitive cook stoves that are fueled with biomass (wood, straw, crop waste, dung, etc…). These fires pollute homes and the environment, leading to serious health problems and contributing to global climate change. Additionally, fuel must be purchased at relatively high prices, or many hours are required to gather sufficient fuel each day. High fuel costs add in the limited financial resources, and collecting for fuel limits time available for education or other economically productive activities.

Each problem associated with biomass combustion – confining people in poverty as well as the negative health and environmental impacts – may be alleviated by engineering biomass cook stoves that promote complete combustion. The ORCA grant received was used to address this issue by developing a power harvesting system that extracts power from the exhaust stream from a traditional Peruvian cook stove. The harvested power is used to power a fan that ventilates the living space while directing more air into the combustion zone, which decreases the fuel to air ratio and leads to more complete combustion of the biomass fuel.

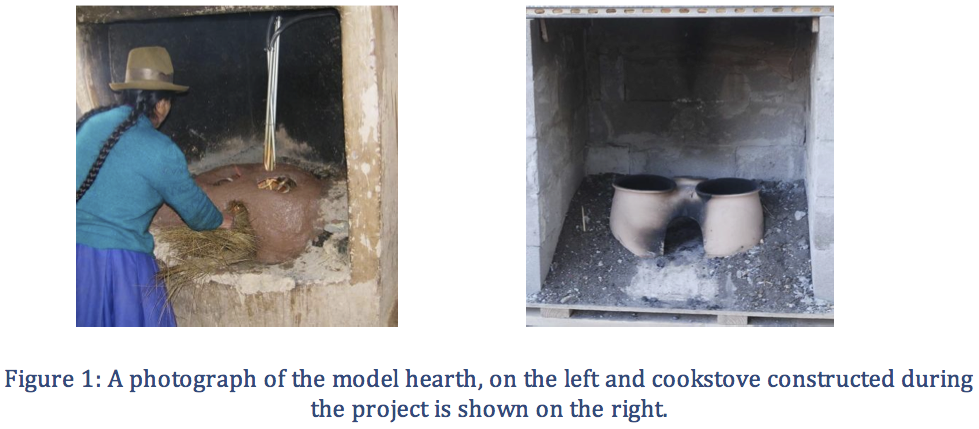

Our team replicated a traditional Peruvian cook stove and built a hearth similar to those commonly found in remote Peruvian villages. This infrastructure enabled the team to design and test a system. Preliminary assessments of this system were conducted using a carbon monoxide monitor and filters to measure the improvements in combustion process due to the increased air flow, and these assessments indicate that the project was successful. A photograph of the model hearth and cook stove built by the team in shown in the figure 1 for comparison.

Preliminary assessments were conducted using a carbon monoxide (CO) monitor and filters to measure the improvements in combustion process due to the increased air flow. Three tests were run without using the fan; three tests were run using the fan. So, data for a total of six combustion tests were gathered. The same procedure was followed each time in order to ensure that the comparison of results was valid.

Each test began by placing 10 g of straw at the center of the cook stove. The fire was started by igniting the straw kindling. Next, 100 g of seasoned firewood was arranged above the straw in the shape of a teepee. The seasoned firewood has a moisture content of 20 – 25%. After starting the fire, another 100 g of seasoned fire wood and 100 g of wood taken from a discarded pallet were added to the flames. Once the fire burned out, any remaining fuel and all coals and ash were removed from the stove.

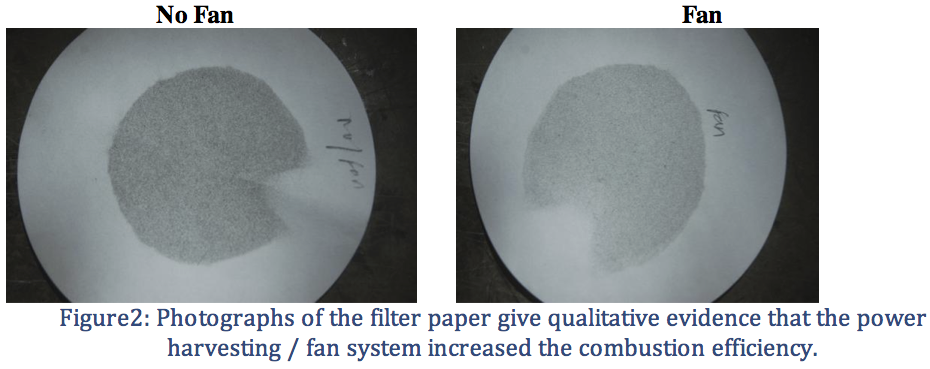

A computer fan ventilated the living space by drawing air from the surrounding into a duct that was buried beneath the cook stove, and the air exited the duct at the base of the flame, which resulted in good mixing of the combustible material resulting from pyrolysis of the fuel and the oxygen in the air stream. The reduced CO concentrations in the exhaust stream when the fan was run indicated that the combustion process was more efficient. Another conclusion was that the fan extended the time the fire burned, indicating that more of the combustible material in the fuel underwent pyrolysis and was consumed, which is another indication of increased combustion efficiency. In addition to monitoring the CO concentration in the exhaust stream, filters were used to collect the particulate matter from the exhaust stream. Photographs of two representative filters are shown in Figure 2.

The greater density of particulate matter seen in the photograph of the filter used without the fan compared with the photograph of the filter used with the fan gives qualitative evidence that the fan increased the combustion efficiency. Attempts to quantify the amount of particulate matter by weighing the filters before and after exposure to the exhaust stream were unsuccessful. Despite precautions such as carefully handling the filters using plastic gloves, these measurements were inconclusive. In many, but not all cases, the filters weighed less following deposition of the particulates than before. It is hypothesized that these erroneous results are due to the fact that moisture was driven out of the filters while they were exposed to the exhaust stream. The results obtained to date are preliminary, and it is anticipated that more definitive qualitative and quantitative data will be obtained if further research is conducted by future teams.