Weston Baxter and Dr. Dale Tree, Department of Mechanical Engineering

Goal/Purpose of the Project

This project aimed to produce and test an opaque surface on an optical fiber tip that will survive temperatures up to 3000 K. The optical fiber is to be used to measure flame temperature in oxy-coal and other combustion processes.

Importance of Project

Oxy-fuel combustion, is one of the leading technologies for the capture and sequestration of CO2 (a source of global warming) from coal fired power plants [1]. Accurate measurements of gas temperature in this process (and other coal combustion processes) are difficult to obtain and is thus poorly characterized. In collaboration with Dr. Jones (also Mechanical Engineering), Dr. Tree is developing a simple and practical method of measuring temperature using an optical fiber pyrometer. Significant initial testing is necessary to prove this concept in order to receive further funding from the National Science Foundation to advance the development of this method.

Background

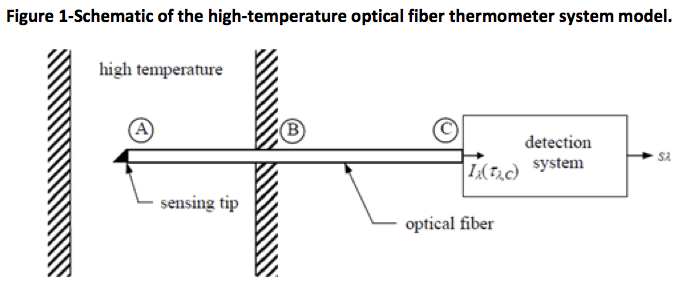

A pyrometer is an instrument designed to infer temperature from the spectral intensity emitted by an object [2]. The proposed method uses an optical fiber placed within the combustion gas which is heated to the gas temperature and emits spectral radiation which is transmitted to a detector through the fiber as shown in Figure 1. The tip of the fiber is made into a black radiating cavity by coating the fiber tip with an opaque surface. In the past, platinum has been sputtered on the surface to form the black radiating cavity but the platinum has a limited temperature (~ 1800 K) which is well below the target temperature of 3000 K. The fiber is made of quartz or sapphire and can be obtained at very small diameters (less than 10 µm). The fiber will be placed in a protective ceramic sleeve to reduce the temperature along the fiber length except for a short distance protruding into the flame. The opaque surface is needed to eliminate flame radiation from entering the fiber and to produce a black body cavity on the fiber tip in which case it can be assumed that all radiation detected is emitted by the blackbody cavity [3,4]. This research will investigate different options for covering the tip of this fiber.

Methods

The initial approach was to sinter carbon laden material into the surface of the fiber. Materials to be investigated include: heavy fuel oil, black liquor, and tar. The idea being that once a fiber is coated, light transmittance through the fiber can then be measured by exposing the fiber tip to a tungsten lamp (very bright light) and measuring the light output of the fiber with a spectrometer. Once a sustainable coating is found, it will be tested in an oxy-coal flame.

This approach was separated into two parts. First, carbon laden materials were exposed to the fiber after the fiber had reached the desired temperatures. In the second case, the material was secured to the surface of the fiber and together heated to the desired temperatures. In both cases, the material failed to create a coating with any notable fidelity. Similar experiments were conducted using a wide range of materials including carbon, silicon, and metal (aluminum and iron) based materials. Finally, this experiment was extended to include an attempt to coat the fiber by exposing it to flames with high soot content. While many of the individual experiments produced a coating, all were either too porous to use or would not properly bond to the fiber.

Results and Future Work

A more extensive literature review identified reasons behind sputtering platinum in existing fiber measurement devices. Previous experiments similar to those conducted for this project resulted in the same failures seen in this project of porosity and inability to adhere the coating to the fiber. Sputtering and chemical vapor deposition (CVD) are two techniques proven to work around these issues. Current materials used in the sputtering and CVD processes melt or degrade at oxy-fuel temperatures. Through researching other high temperature applications, such as rocket propulsion, we identified several materials with melting points in the range of this project [5]. Industry leaders and Professor Allred in the physics department, who works extensively in sputtering and CVD, have been contacted for possible future collaboration in processing fibers for this work.

The materials most suited for this coating appear to be HfC and BN due to performance in other high temperature applications, coefficient of thermal expansion similar to that of the fiber and relative prevalence of these materials in industry. To date, enough information has been gathered to successfully apply for NSF funding to develop the OF Pyrometry technique. Additional work is needed to test the response of the fiber and clarity of the signal coming from those fibers. The successful development of an OF pyrometer for this application must also account for reliability and financial concerns governing the final development and production of the product.

Scholarly Sources

- http://www.netl.doe.gov/publications/press/2010/10033-Secretary_Chu_Announces_FutureGen_.html, Accessed on Feb 12, 2011.

- Dils, R. R., “High-Temperature Optical Fiber Thermometer,” Journal of Applied Physics, (1983) 54, 1198 – 1201.

- Jones, M. R. and Barker, D. G., “Use of Blackbody Optical Fiber Thermometers in High Temperature Environments,” AIAA. Thermophys. Heat Transfer, (2002) 16, 306 – 312.

- Barker, D. G. and Jones, M. R., “Temperature Measurements Using a High-Temperature Blackbody Optical Fiber Thermometer,” Journal of Heat Transfer, (2003) 125, 471 – 477.

- http://www.ultramet.com/materials101.html, Accessed on June 20, 2012.