Jeffrey Maas and Dr. Aaron Hawkins, Electrical Engineering

Microfabrication of Electron Sources as it applies to Chemical Sensors has been a useful project. With the decreasing dimensions of the handheld mass spectrometer it is becoming increasingly more important to develop an on board electron source for localized source emission. This project has been undertaken as of November of 2005 and continues to be an important aspect of research. This project has proven to be one of larger proportions than envisioned at first outset. Despite all that has yet to be done progress has been made. Sacrificial Layers have been identified as well as potential metals for the electron source. Several structures have been constructed and have been included for demonstration of progressing technique.

The ideal sacrificial layer has been one of the most illusive solutions to discover in this project. It was the desire in the beginning and will continue to be so that the sacrificial layer is photodefinable. However, most photodefinable substances are essential light sensitive epoxies. As soon as the photoresist has been hardened it becomes most difficult to remove. At this point anything that removes the organic photoresist will likewise remove the metal filament itself. I have conducted several tests to see if there was a point in which a specific shape could be attained (as described in the proposal) that would still remove in acetone. It was also discovered that 180C was about as close to the magic temperature as any for AZ3330 type photoresist. This was only closely what we had in mind and eventually we decided to go with a heat degrading PPC which when heated would decompose and better subject itself to solvents such as acetone. This was the missing link that finally allowed us to continue on with the project.

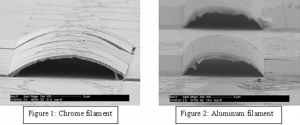

There are many different metals that would be acceptable for this type of emitter. Ideally it would be able to get hot without melting, as well as still be somewhat soft to avoid too many stress points. Our metal had to be ductile, have a high melting point, and be eager to give up electrons. This we found in Chrome, Nickel, and Tungsten. Tungsten being the hardest of the three but is often used as a filament in several applications.

As you can see by these images the metal is able to remain suspended after the sacrificial material has been removed.

There still remains much to be worked on with this project. This will all be apart of its magnificent future. There is currently an academic journal article being written on the chemical sensors that these structures are apart of. The projected publisher will be the Journal of Analytical Chemistry and should be appearing at the beginning of 2007.

I appreciate the financial help in this project as I have taken it underway. I hope that we will all see the effects of the microfabricated ion source come into play in the scientific world.