Aimee Worthen Birdsall and Dr. Spencer Guthrie, Civil Engineering

INTRODUCTION

Chloride penetration into concrete is the main cause of the rapid deterioration of concrete structures due to corrosion of reinforcing steel . This problem is especially a concern in chloride-laden environments. However, these chlorides cannot stop being applied because they are applied as deicing salts to maintain traffic during winter months. A solution many departments of transportation have investigated is to cut off the transportation path of these aggressive ions by adding a barrier between the concrete surface and the chloride agents . However, departments of transportation vary in their ideas about when this surface treatment should be applied.

Previous researchers have compared the relative utility of different types of surface treatments to one another, modeled different diffusion coefficients given varying parameters, and even investigated the effect of surface treatments on diffusion coefficients. Furthermore, previous research concerning application of surface treatments and its effects on chloride diffusion was based on laboratory specimens rather than actual bridge decks. However, the literature is generally absent of information on modeling diffusion coefficients for the purpose of identifying maximum timing of surface treatment applications. Therefore, the specific objectives of this research were to numerically model chloride concentration profiles within bridge decks with and without stay-in-place metal forms (SIPMFs) in order to determine the optimal timing for placement of overlays.

PROCEDURES

In order to supplement the need for further research regarding the placement of surface treatments, the Utah Department of Transportation (UDOT) funded a research project at Brigham Young University (BYU) during the summer of 2005. UDOT personnel selected six concrete bridge decks with SIPMFs and six without SIPMFs for testing.

Numerical Modeling

To facilitate analysis of chloride concentration profiles, the midpoint of each depth interval was computed, and chloride concentrations at 1-in. depth intervals were then determined for each test location by interpolation. Average chloride concentrations at each depth interval were also computed for decks with and without SIPMFs to enable comparison of the overall chloride concentration profiles. These profiles were then averaged for each deck in order to facilitate the finding of a representative chloride concentration diffusion coefficient.

In order to predict the diffusion coefficient for each bridge deck, chloride profiles were numerically modeled using existing software created by the National Institute of Standards and Technology . This program simulates chloride diffusion based on a one-dimensional model. The majority of the input variables were determined based on conditions typical of the tested bridge decks. Three input variables differed one each bridge deck: total duration of exposure, depth of reinforcement, and diffusion coefficient. Each of these values was dependent on the individual deck being modeled. In order to calibrate the computer program to fit the data within the scope of this research, surface concentrations, boundary conditions, and diffusion coefficients specific to the field tested chloride concentrations needed to be obtained.

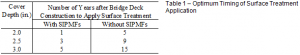

Following model calibration, the effects of overlay placement at different deck ages was simulated using the surface treatment option in the NIST computer program. Surface treatments applied at 0-15 years were simulated over a period of 30 years. These individual values were then used to identify chloride concentrations at different cover depths (2, 2.5, and 3 inches) that should not be exceeded if the epoxy overlay is to provide the intended protection against corrosion of the reinforcement.

RESULTS AND DISCUSSION

Final graphs of computer simulations over a 30 year period are summarized in Table 1. As a trend within these results, the greater the cover, the longer an agency could prolong the application of a surface treatment. This could be explained by the fact that it would take chlorides more time to diffuse to deeper levels of reinforcement, and therefore not corrode for a longer period of time. Another trend detected was that decks with SIPMFs needed a surface treatment applied at an earlier year than decks without SIPMFs. As an explanation of this trend, decks with SIPMFs experienced earlier corrosion than decks without SIPMFs and therefore needed a surface treatment applied at an earlier date.

Given these research findings, engineers should consider the variables of cover depth and SIPMFs in determining when to apply a surface treatment to their bridge deck. In order to maximize the life of a bridge deck, surface treatments should be applied at the years suggested by these results.

References

- Zhang, J. Z., I. M. McLoughlin, and N. R. Buenfield. Modelling of Chloride Diffusion into Surface-treated Concrete. Cement and Concrete Composites, Vol. 20, No. 4, 1998, pp. 253-261.

- Swamy, R. N., and S. Tanikawa. An External Surface Coatin to Protect Concrete and Steel from Aggressive Environments. Materials and Structures, Vol. 26, No. 162, 1993, pp. 465-478.

- Prediction of a Chloride Ion Penetration Profile for a Concrete. National Institute of Standards and Technology, Gaithersburg, Maryland. http://ciks.cbt.nist.gov/~bentz/clpen2.html. Accessed July 7, 2006.