Bryan Wilson and Dr. W. Spencer Guthrie, Civil and Environmental Engineering

Problem Statement

The access road to a coal mine facility was determined to have failed by BYU researchers after a field investigation in 2008. The road surface was heavily degraded by severe transverse, longitudinal, and fatigue cracking. Deep depressions coincided with the transverse cracks causing extremely poor ride quality. Subsurface testing revealed the base and subgrade to be very low quality with unusually high moisture contents and low dry densities.

Full-depth reclamation (FDR) was recommended to repair Black Butte Road. The technique involves complete pulverization and in-situ recycling of the existing asphalt and base layers, thus eliminating any possibility of reflective cracking and simultaneously providing significant economic and environmental benefits. FDR requires the addition of a stabilizing compound such as portland cement, fly ash, lime, blast furnace slag, etc. to add strength to the pulverized compounds. These products have different modes of stabilization, and their effectiveness varies with soil type and possibly with freezing.

A new pavement design was requested for the mine access road, including specifications for stabilizer type, aggregate, and water.

Scope

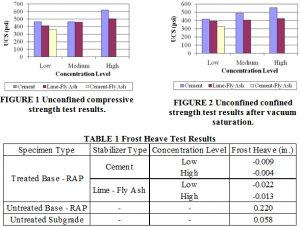

The laboratory research for this project used two materials: existing base and reclaimed asphalt pavement (RAP). These were mixed together and treated with two primary stabilizers, portland cement and lime-fly ash (LFA), and one secondary stabilizer, portland cement-fly ash (CFA). The primary stabilizers were tested at three concentrations associated with an estimated “low,” “moderate,” and “high” strength. The CFA concentration was estimated to be equivalent to the “low” strength samples. Three replicate samples of each stabilizer type and concentration were created and tested for unconfined compressive strength (UCS) under normal conditions and after vacuum saturation conditioning (a weakening procedure that highly correlates with freeze-thaw conditioning.) One “low” and “high” concentration sample of each primary stabilizer was made for frost heave testing. A control sample of untreated base-RAP and an untreated subgrade sample were also made for frost heave testing.

Laboratory Results

The resulting average UCS values of each sample type without and with vacuum saturation conditioning are shown in Figures 1 and 2, respectively, and tabulated results of the frost heave tests are shown in Table 1. The satisfactory UCS value for a cement-treated base (CTB) is 400 psi. All of these designs except the CFA design met the UCS criteria and are very likely to withstand the negative effects of freeze-thaw action. The frost heave samples did not experience heaving when stabilized. The samples that remained untreated did experience heaving, but it was minimal.

Research Accomplishments

Using this data and other field data, I designed the pavement layers for submittal to a local engineering firm as part of a full-scale road restoration design for the coal mine. The design was implemented, and reconstruction occurred over the course of a few weeks during September of this year. We received additional funding to carefully monitor the implementation of the CTB construction procedure. The engineers and contractors were impressed by the FDR process and current performance of the CTB.

In addition to providing written documentation to project partners, I prepared a technical paper based on my research results for submission in the Rocky Mountain Regional Conference, an annual collegiate civil engineering competition, and was pleased to receive first place for my paper and presentation.

Additionally, this project will be used for my thesis report, which is nearly completed. I will also prepare a journal paper for submission to the Transportation Research Board for presentation in the annual conference in Washington, D.C. and publication in the Transportation Research Record.