Richard Christensen and Dr. Richard Balling, Civil and Environmental Engineering

During the past 60 years, ever since the discovery of mass produced steel, the world has used this steel to produce buildings that touch the sky. These skyscrapers have become a point of competition and interest throughout the world. Each country tries to outdo the next in building height and beauty.

What is not discussed nor seen is the foundation that keeps and will continue to keep these buildings standing tall throughout the coming years. The design of these foundations has been revolutionized in the recent years; one of these changes is the shifted from using standard piles to rectangular barrettes. During the past 30 years the use of barrettes has become more commonplace, but there is little information showing the effectiveness of these barrettes opposed to piles1.

History

Barrettes have much of the same purpose and design as the piles. Barrettes were developed about 30 years ago, but have not been widely used. The main difference between a barrette and a pile is the shape and the equipment used to construct a barrette. While a pile is typically circular in shape.

Recently Eastern Asia has used barrettes in many projects including the ICC towers in Hong Kong as well as in a Alfaro’s Peak which is a 28-story residential building in the2.

Barrettes differ from piles in the fact that they take on a rectangular shape. A standard barrette cross section ranges from 4-23 by 2-5 feet. The length of these barrettes can reach over 170 feet down into the ground. 3.

Installation

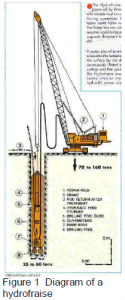

Barrettes are typically installed using a hydrofraise. A hydrofriase is essentially a large chainsaw that cuts into the ground. Figure 2 shows an example of a hyrdrofraise and labels all of the major parts4. They typically go about 200 feet into the ground, but have the capabilities to go up to almost 500 feet.

Another method of creating barrettes is the use of a clamshell. The clamshell is dropped down into the hole and then closes in on dirt and is able to carry the dirt back up out of the hole.

Barrettes are often times used when slurry walls are used because they use the same equipment. This saves on costs in both time and equipment because there is no longer the need to rearrange the equipment and move stuff in and out which is a slow procedure5.

Technical Advantages

Because of barrettes rectangular shape they are not able to take equal amounts of loading from all directions. While this can be a hindrance if loading is expected from all directions, it can also serve as a bonus. Wind typically comes from a prevailing direction and rarely comes from other directions. Using this knowledge barrettes can be placed such that the strong axis is aligned with the prevailing wind direction allowing this side to take the stronger loading while the weak axis can easily handle the smaller loads.

Material is able to be saved when creating the barrette because the dimensions can be changed to handle the loading.

Case Study

The ICC (International Commerce Center) currently under construction is one such building that uses this new technology. The bedrock was located between 60 and 130 meters under the ground and specialized equipment would have been required to be shipped in to drill piles that deep. Instead of doing this barrettes were utilized.

A total of 241 barrettes were used in the foundation of the ICC building, each extending a mere 26 meters into the ground. Because of their ability to orient the barrettes, they were not required to go as far down into the ground as the piles would have had to.

Conclusion

The use of barrettes has revolutionized foundations throughout East Asia, and the method is continuing to develop and gain steam. It is only a matter of time before this method catches on in the United States.

On a personal note, the opportunity I had to take a trip to China and visit the buildings under construction there was a trip of a lifetime. It has opened my eyes to the magnitude of the projects that are out there and made me excited to be a part of the future. I learned most of my information about barrettes in the BYU library and was disappointed about the amount of information I was able to learn while on the site visit of the ICC building. However, while the information learned wasn’t as technical as I had hoped, the experience and standing in the building using the foundation system I had spent so much time researching was an experience I will not soon forget.

References

- Ng, Charles W. W., and G. H. Lei. “Performance of Long Rectangular Barrettes in Granitic Saprolites.” Journal of Geotechnical & Geoenvironmental Engineering 129.8 (2003): 685.

- Fellenius, Bengt H., and Ameir Altaee. “O-Cell Testing and FE Analysis of 28-m-Deep Barrette in Manila, Philippines.” Journal of Geotechnical & Geoenvironmental Engineering 125.7 (1999): 566.

- Zhang, L. M. “Behavior of Laterally Loaded Large-Section Barrettes.” Journal of Geotechnical & Geoenvironmental Engineering 129.7 (2003): 639.

- “Hydrofraise.” <http://www.duchemin.org/jj/stage/HYDRO2.HTM>.

- Ng, Charles W. W., and G. H. Lei. “Performance of Long Rectangular Barrettes in Granitic Saprolites.” Journal of Geotechnical & Geoenvironmental Engineering 129.8 (2003): 685