David Jarvis and Drs. David Jensen, Civil and Fernando Fonseca, Civil and Environmental Engineering

Background

The objective of this research was to determine the flexural strength of concrete beams reinforced by the rectangular carbon fiber IsoTruss. The rectangular IsoTruss is a threedimensional composite grid structure patented by Brigham Young University. It is a modification of the regular IsoTruss that is also being researched at Brigham Young University.

Research Methods

Fabricating the Rectangular IsoTruss: Rectangular carbon fiber IsoTrusses are currently being fabricated in the Civil Engineering Department at Brigham Young University. To produce the IsoTruss, continuous strands of carbon fiber are impregnated with an epoxy resin and then wound around a rotating mandrel that offers the desired shape and size. Each strand of carbon fiber is called a tow. The number of tows used determines the diameter of the individual members that makes up the IsoTruss. After winding is complete, the mandrel is placed in an autoclave to allow the impregnated fibers to cure. Once cured the IsoTruss is removed from the mandrel and can be placed in concrete as reinforcement. A picture of the IsoTruss is shown below.

Construction of Concrete Beams: All of the beams were 4 (four) inches wide by 6 (six) inches tall, and 30 (thirty) inches long. The forms and concrete mix needed for the fabrication of the beams were provided by the Center for Advanced Structural Composites at Brigham Young University.

Testing of Concrete Beams: The beams were subjected to a four point flexural test to determine flexural strength using the Baldwin Testing and Data Acquisition System at Brigham Young University. Nine beams were tested. The test parameters were:

• Three beams with 12 (twelve) tows of carbon fiber.

• Three beams with 18 (eighteen) tows of carbon fiber

• Three beams with 24 (twenty-four) tows of carbon fiber

Results

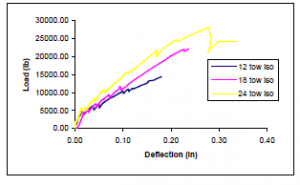

The figure to the right shows the load verses deflection graph of the second round of tests. All of the rounds had similar graphs. As expected, increasing the number of tows increased the maximum load in a nearly linear fashion. It also increased the initial stiffness of the beam. Calculations showed that the strength to area ratios of the carbon fiber IsoTruss are four times higher than the predicted strength to area ratios of current steel Deflection curve..

Figure 3. Load Vs. Reinforcement

Conclusions

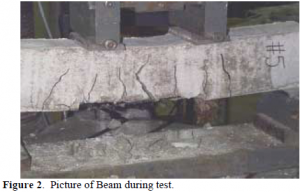

Although the rectangular IsoTruss reinforced concrete beam showed high strength values, all of the beams failed in a brittle manner. This is atypical and an undesirable behavior in concrete structures. Prior research with the standard six node IsoTruss demonstrated a ductile failure and still maintained high strength values, making it the more efficient beam.