Sara Ludlow, Dr. Gregory T. Carling, Department of Geological Sciences

Pollution of Lake Titicaca has become a major threat to the health and lifestyle of the Uru people who use the lake water for their daily needs. Cities along the coast dump untreated sewage directly into the lake introducing dangerous microbial levels of Escherichia coli. Runoff from nearby mines increases the risk of toxic levels of lead, arsenic, and other heavy metals. Previous members of the ongoing Global Engineering Outreach (GEO) program identified biosand filtration as a viable option for mitigating these risks. As such, they implemented single stage biosand filters in the community, but they were never able to assess their effectiveness. We analyzed the current filtration method, identified metrics for improvement, and modified the filter design to better meet current health standards.

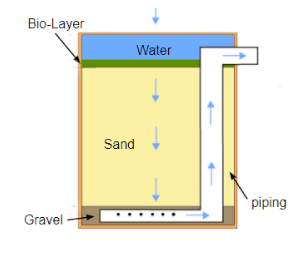

In the original design shown in Figure 1, sand was sieved, washed, and placed into a bucket at a height of 0.4 meters with a layer of gravel at the bottom. In biosand filters, water is purified via mechanical trapping, adsorption and predation. Mechanical trapping and adsorption occurs as suspended materials are trapped by, or become attached to, the sand grains. Predation is the consumption of bacteria by microorganisms living primarily in a microbial film known as schmutzedecke that exists atop the sand layer. This biolayer naturally forms over about two weeks as water is run through the system.

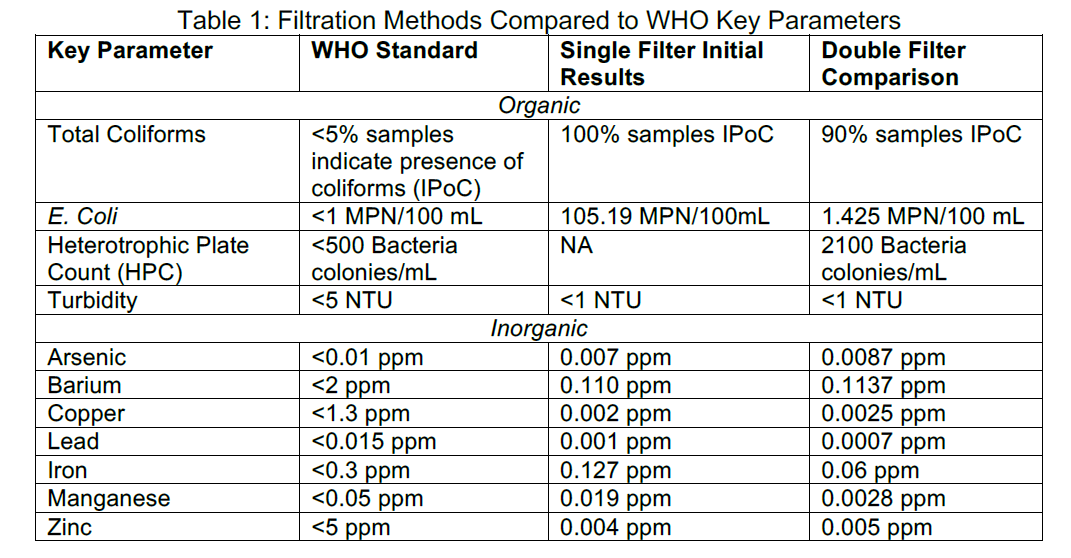

From the World Health Organization, we identified 14 key drinking standards. Due to budgeting and scheduling challenges, we narrowed our focus to the key parameters shown in Table 1. Initial tests from spiking test water with heavy metals revealed that the single stage filter appeared to be fairly capable of controlling inorganic levels. Bacterial tests indicated that the single stage filter was removing approximately 70% of total coliforms and 60% of E. Coli. However, as the test water grew more nutrient and phosphate rich, predation in the biolayer was compromised and instead promoted the growth of bacteria throughout the filter. Further testing revealed that this could be mitigated by cleaning the filter thoroughly with bleach every two months.

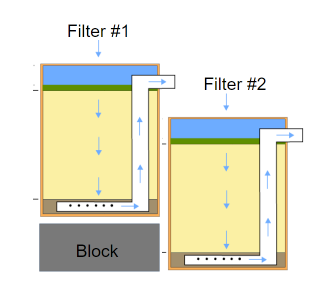

Addressing the deficiency in microbial removal became our focus of the design changes. We considered multiple additives to improve filtration efficiency including activated carbon, chitosan, and diatomaceous earth. Though some of these showed promise, none were plausible solutions given the limited resources of the Uru people. Given these stringent design considerations, we decided that the best short term solution was to create a double layer filtration system (Figure 2). This design has three advantages: 1) it allows for larger filtration volume to aid with mechanical trapping and adsorption, 2) it adds a second biolayer to aid with predation, and 3) it allows for a robust maintenance/cleaning regimen. The stages of the filter can be cleaned every two months on an alternating monthly schedule to avoid completely compromising the microbial filtration ability of the filter. Using this double stage filter, total coliform and E. Coli removal jumped to 83% and 86% respectively. Key parameter results are displayed in Table 1.

Analysis of the current filter system has played a crucial role in the Uru filtration project. Not only has it helped us improve the effectiveness of their current system, but it has helped us understand the limitations of using biosand filters. It is clear that biosand filters, while they do improve water quality, cannot produce water that meets WHO standards. Future projects will explore other means of filtration (ie. solar distillation, bleach disinfection, diatomaceous earth pressure systems, etc.) to better meet these standards. We are one crucial step closer to helping the Uru people have a higher quality of life.

Figure 1 – Original biosand filter design. Water runs through the biolayer, sand, and gravel before returning up through the PVC piping via natural physics. Sand particles are <0.7mm in diameter and gravel diameters can be 0.7-10mm.

Figure 2 – New double stage biosand filter design. The two stages are cleaned on alternating schedules to keep at least one active biolayer in the system. The cleaned filter will take about two weeks for the biolayer to return to full potency.