Andrew Orme and Dr. David Fullwood, Mechanical Engineering Department

Introduction

Magnesium is a potential replacement for steels and aluminum in strength applications. Despite desirable strength and weight properties, magnesium is costly to manufacture. To reduce manufacturing costs, extensive research has been done on is a phenomenon called twinning, where a large group of magnesium atoms collectively reorient from a base orientation to a new orientation. This reorientation caused by twinning has the potential to enable easier material deformation, allowing for less costly manufacturing. Our research group pursued a novel approach to twinning research by using data mining and machine learning algorithms. Data collected from samples of magnesium using a scanning electron microscope (SEM) method called electron back-scatter detection (EBSD) is used to train machine learning models. This approach was shown to have potential to assist the materials science community in their quest to understand the twinning phenomenon [1].

This projected aims to 1) expand the use of machine learning by conducting a study into the effects of applied strain on twin prediction models and 2) build a dataset that simplifies validating machine learning and statistical models. This report briefly outlines the results from work conducted to accomplish both tasks.

Methods

Samples of a magnesium alloy (Mg AZ31) were mechanically and chemically polished in preparation for scanning in an SEM. Data for the study of strain was collected using standard EBSD methods. Multiple samples were scanned, each at a different level of compression. The raw data from the microscope was processed using OIM Analysis and Matlab to produce a dataset appropriate for use in machine learning. Using the machine learning software WEKA, the data was filtered and used to train a J-48 decision tree algorithm. This algorithm produces a simple-to-interpret decision model that when analyzed, yields insight into the relative importance of factors when making a predictive decision. Several models were created and compared to investigate variations connected to level of strain.

To accomplish the second task, it was decided to collect EBSD data from a sample of magnesium at various strains during compression. After polishing, a sample was loaded into a special microscope attachment capable of compressing the sample while inside the microscope. An area on the surface was identified and a scan with no applied strain was taken. In small strain increments, the sample was compressed, with a scan occurring after each increase in compressive strain. This method is referred to as an in-situ scan, and allows for observation of twin formation and growth at very early stages. Such observations enable a researcher to directly verify if predictions made by a machine learning or statistical model were correct. To be useful, small strain increments are required, as twins grow rapidly when a strain is applied.

Results

Analysis of the decision trees made by WEKA illustrated three key characteristics that twinning depends on which vary with strain. They are parent grain size, basal Schmidt factor, and average grain misorientation.

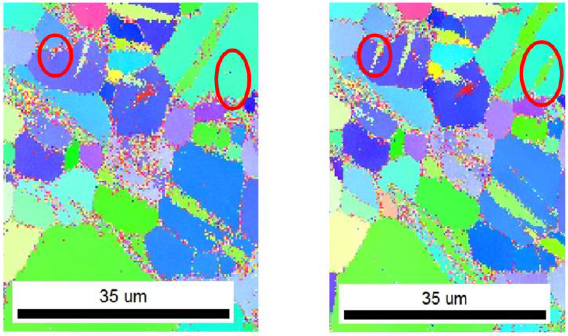

The in-situ scans proved difficult, with the only valuable dataset being a proof-of-concept dataset. This data is illustrated in the included image. Note the small spike-like variations circled in red; these are twins in early stages of growth.

Discussion

The strain variations uncovered by WEKA are being compared with similar variations noted in literature, with interesting results. Some of the variations uncovered, like the one for parent grain size, have already been accounted for in many statistical models. However, variations in grain misorietation are not as prevalent in current models. Inclusion of such variations could positively impact these models and increase their predictive capabilities.

As noted, the in-situ scans proved difficult to accomplish. This was due to the small strain steps required to produce a valuable dataset. It was found that the microscope attachment used was not capable of the required step size, meaning a new method of compressing the sample will need to be found. The proof-of-concept data uses larger strain steps, showing the method will work, but does not give the insights into early twin development needed. Future refining of the in-situ methods will allow for smaller strain steps and observation of twin activity in earlier stages of development.

Conclusion

This project has helped refine machine learning techniques and has expanded knowledge about strain-based variations of several key magnesium characteristics. In-situ methods for collecting data on magnesium were explored. Limitations in current hardware at BYU were uncovered, with plans developed for future work to address them. The work conducted assists as the materials science community attempts to better understand the twinning phenomenon in magnesium.

[1] A.D. Orme, I. Chelladurai, T.M. Rampton, D.T. Fullwood, A. Khosravani, M.P. Miles, R.K. Mishra, Insights into twinning in Mg AZ31: A combined EBSD and machine learning study, Comp Mater Sci 124 (2016) 353-363.