Jeffrey Clark and Dr. Paul Savage, Chemistry and Biochemistry

Introduction

The accumulation of biofilm on urinary catheters and endotracheal tubes is one of the leading causes of hospital-acquired infection1. A variety of techniques have been developed to help mitigate this problem. One of these techniques is to coat devices with a biofilm-resistant polymer brush coating. Although these coatings may prevent adhesion by bacteria, they do not actively kill invading bacteria.

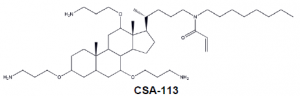

My project has been an attempt to improve upon these polymer-brush coatings by covalently incorporating antimicrobial ceragenins into the coating. We have shown that the addition of the ceragenin CSA-113 could synergistically increase the polymer’s ability to inhibit bacterial aggregation by adding bactericidal activity. My responsibility has been to investigate the construction of these mixed-polymer coatings.

Methods

Initially, I decided to follow a method created by Cringus-Fundeanu et al2. Small silicone coupons were washed and then treated in a plasma cleaner. They are then functionalized using 3-aminopropyltriethoxysilane (APS) in toluene, and then washed with toluene in a soxhlet to remove excess APS. The coupons are then stirred in 4-(chloromethyl)benzoyl chloride in dichloromethane. This chloromethyl group could then react with the conjugated double bonds of CSA-113 and acrylamide to form a mixed polymer.

We found that this method had high bactericidal activity, but it did not adequately resist the formation of biofilm. Using an amine-sensitive ninhydrin dye, I determined that CSA-113 and other chemicals had penetrated the coupon and were present at its core. This indicated that CSA-113 could be present in solution, and not just at the surface of the coupon. Therefore, we could not determine whether a significant amount of CSA-113 was available in the polymer matrix.

To fix this problem, we developed a more rigorous procedure to prevent CSA-113 from being available in solution, and to ensure that more antimicrobial activity occurred on the surface. I washed the coupons in a toluene-filled soxhlet to remove result-confounding silicone monomers. After plasma treating the coupons, I boiled them in water to create more OH groups on the surface of the coupon. Then, to prevent surface penetration, these coupons were treated in a gas phase reaction using the more volatile 3-aminopropyltrimethoxysilane. Tests with ninhydrin showed a dark purple coating on the surface, with no functionalization within the core of the molecule. A graduate student then polymerized these coupons with a variety of reagent concentrations.

Conclusion

Qualitatively, ninhydrin staining made it easy to see that our new methods incorporated a significant amount of CSA-113 into the polymer-brush coating. Also, tests by a microbiologist indicated that these samples had minimal bactericidal activity in solution, but some reagent combinations did reduce the quantity of biofilm by more than 90%. Therefore, incorporation of antimicrobial CSA-113 into a polymer-brush coating can synergistically decrease the amount of biofilm formation on a silicone coupon.

Future Work

This work demonstrates a simple proof of concept. However, further optimization of reagent quantities and techniques during the polymerization step could yield significantly better results. Also, these tests were performed under fairly mild conditions for biofilm formation. Further tests need to occur in a CDC-produced bioreactor. As always, a variety of media will need to be tested. After testing in media, animal tests will need to be performed before human trials can be conducted.

References

- Richards, M. J.; Edwards, J. R.; Culver, D. H.; Gaynes, R. P.; Crit. Care Med. 1999, 27, 887-892.

- Cringus-Fundeanu, I; Luijten, J; van der Mei, H. C.; Busscher, H. J.; Schouten A. J.; Langmuir. 2007, 23, 5120-5126.