Tenli Waters and W. Spencer Guthrie, Civil and Environmental Engineering

The purpose of this project was to measure thermal properties of natural-colored and darkened portland cement concrete in order to explain observations from field data already collected. While portland cement concrete pavement offers a durable surface and long service life when designed and constructed properly, selected concrete pavement sections require expensive winter maintenance treatments to clear snow and ice. One method of potentially reducing winter maintenance costs is darkening the concrete pavement. Darkening the concrete reduces its albedo, or whiteness, and should therefore promote higher pavement surface temperatures through increased absorption of radiation energy from the sun. In winter, darkened concrete pavement should then melt snow and ice more quickly, all other factors the same, than natural-colored concrete pavement.

The Utah Department of Transportation (UDOT) has facilitated research at a site located at the intersection of 1400 North and 1000 West in Logan, Utah. The intersection was constructed using both natural-colored and darkened portland cement concrete pavement. During placement of the concrete, numerous samples were cast from both the natural-colored and darkened concrete sections, and the cylinders were brought back to the BYU Highway Materials Laboratory for testing.

Electronic sensors measuring temperature and volumetric moisture content were installed in the pavement during concrete placement and were connected to a data logger. Sensor data are currently being transmitted via cellular service to a website, from where they have been downloaded on a regular basis for analysis. Thermocouple wires were also installed prior to concrete placement and were used to measure subsurface temperatures during quarterly visits to the site. During these quarterly visits, surface temperatures were also measured using infrared thermography.

Through these measurements, we have documented variations in surface and subsurface temperatures in both the natural-colored and darkened concrete pavement through complete daily cycles in all four major seasons typical of northern Utah. We have also computed thermal gradients within the concrete and examined the relationships between surface temperatures, thermal gradients, and air temperatures.

Laboratory testing on the concrete cylinders was needed to supplement the field data already collected. This laboratory testing included measuring the thermal conductivity of the concrete cylinders in both saturated and dry conditions. One natural-colored and one darkened concrete cylinder were cast during pavement construction, and were later tested in the Highway Materials Laboratory at Brigham Young University. The cylinders measured 6 in. in diameter and 12 in. in height.

Thermal conductivity was measured using a RK-2 sensor provided by Decagon Devices. A 5/32-in. diameter hole was drilled 60 mm. into the center of both the top and bottom of each cylinder. The hole was filled with a thermal lubricant before inserting the probe to ensure good thermal contact between the probe and the concrete. Three tests were taken in each hole, and the manufacturer’s recommendations regarding the timing between tests were followed.

Saturated testing took place in a concrete curing room with 100% humidity at approximately 85˚F. The samples had been stored in this room since approximately 24 hours after being cast in the field. Dry testing took place after allowing the samples to dry for just over two weeks.

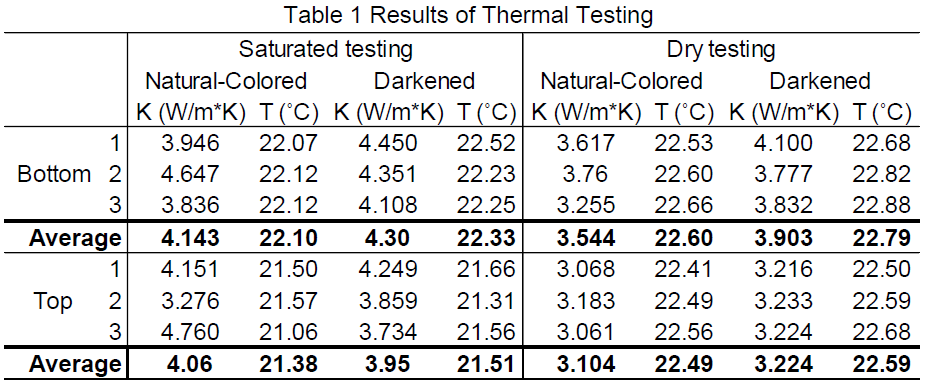

Table 1 displays the results of the thermal testing. Thermal capacity (K) is dependent on temperature (T), so the value for T was recorded, along with the value for K, for each test. In all cases the saturated cylinders had a higher value for K than the dry cylinders. In all cases except one (the top of the cylinders during saturated testing) the darkened concrete cylinders had a higher value for K than the natural-colored cylinders. This means that the darkened concrete pavement should have a higher temperature than the natural-colored concrete pavement when the same amount of energy is put in. This is consistent with the pavement temperature data we collected. Unfortunately, at near-freezing pavement temperatures, the difference is not likely large enough to melt snow and ice on the surface of the pavement.