Phillip Hyatt and Marc Killpack, Mechanical Engineering

Introduction

Many advances have been made in the control, modeling and applications of robots within the past several decades. Robots have been made to operate very quickly within very tight tolerances. Generally, these quick and accurate robots require high gear ratios and vast amounts of electrical power. Recently, however, there has been a growing interest in compliant robots that can safely operate in close proximity with humans and delicate equipment. Compliant robots, because of their smaller motors, backdrivability, and lower torque requirements can be much cheaper and can use much less power than rigid robots. These compliant robots can more easily respond to obstacles in their environment and generally impart lower forces to objects through the use of compliant physical elements, pneumatic actuators, or active control with force sensors. This makes them well suited for applications where we expect them to function successfully around people in environments like homes, schools, hospitals, etc. However, because of the compliant nature of the joints, the control of these robots is inherently different from that of conventional robots and requires more research to be fully understood.

My research was in the method of control called Input Shaping. Input shaping is a method of control used on systems like pendulums which oscillate around the goal position when moved directly there. The input is shaped by moving the system to one or more intermediate waypoints with specific time delays to cancel out the vibrations when the system reaches the final position. While this method is commonly used in simple systems like pendulums, cranes, and one link robot arms, it had never been applied to several serial links of a robot arm like we were able to do through this research.

Methodology

As mentioned before, input shaping had never been applied to systems with multiple serial links in order to reduce the oscillations at the end. This is because input shaping requires that the system being controlled be a linear system. Robotic arms cannot be modeled as linear systems because of the coupling between the joints. For example, when we move our wrist quickly while maintaining arm position otherwise, we exert significant torques in our shoulder and elbow to counteract Coriolis and inertial forces. In the same way as a human arm, a serial link robot arm has joint coupling and this coupling is nonlinear.

Because input shaping could not be applied to a nonlinear system, our solution was to linearize the robot arm using a method called feedback linearization. Using a model of the robot arm and feedback about the velocity and acceleration of each joint we were able to calculate exactly what the Coriolis and inertial forces would be and were able to apply torques to cancel them out. This is the basic idea of feedback linearization and by using it we were able to isolate each joint and treat it as a linear system. Input shaping was applied as described above and the control scheme was implemented on one 7 degree of freedom arm on the Rethink Robotics Baxter robot as seen in Figure 1.

Results

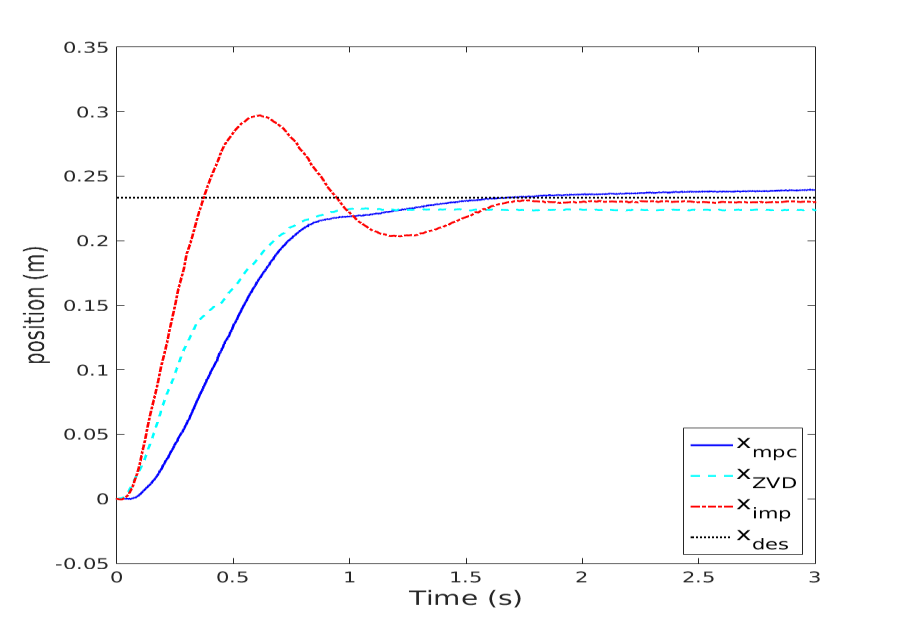

Steps of about 25 cm were sent through the input shaper and the trajectory of the robot hand was tracked. The results of my research showed that by using feedback linearization and input shaping we were able to reduce oscillations at the end effector as seen in Figure 2. While the input shaper was able to reduce oscillations as compared to the normal controller, other controllers developed in our lab were able to reduce oscillations even further. Results from this comparison were accepted as a published paper in the IEEE Humanoids 2015 conference.

Discussion

While the input shaper reduced oscillations, there were several shortcomings which were exposed in our experiments. When large steps in position were commanded, the torque required to carry out the feedback linearization was greater than the motors could supply. Also, our model assumed that we knew the exact parameters (mass, length, etc.) of the arm, which we only knew approximately. These issues caused oscillations and even steady state error in reaching the goal.

Conclusion

It was shown that input shaping can be used on a serial link robot arm to reduce oscillations, however errors in the model and torque limits decrease its effectiveness.

Figure 1 – Rethink Robotics’ Baxter research robot. The input shaping method described above was implemented on this robot and significantly reduced the oscillations.

Figure 2 – The trajectory of the robot hand when commanding a step from 0 to 23 cm along a straight line in 3D space. Red is the normal (PD) controller, light dotted blue is using input shaping, dark blue is using another advanced control method (MPC).