McCall Barger and Christopher Mattson, Mechanical Engineering

Nearly 3 billion people worldwide still cook using open fires or biomass cookstoves, in which they burn wood, charcoal, and other solid fuels1. Over the past ten years, great effort and consideration has been devoted to progressing improved biomass cookstove technology for the developing world. The traditional cookstoves used in developing countries are a significant contributor to current global warming problems; expending 22% of the global black carbon emissions, compared to just 7% from the burning of fossil fuels2. The purpose of this research was to evaluate a cookstove from the Tambogrande region of Peru, called a “channel stove”, in order to find a balance between the cookstove’s technical capability and usability. This project involved designing, building, testing, and optimizing a mechanism that could improve the cookstove’s technical requirements, such as thermal efficiency, fuel consumption, and time to boil, without compromising its functional usability. We predicted that by obtaining a balance between these two requirements, a higher impact could be achieved.

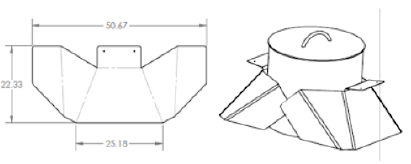

Figure 1: Schematic of the pot skirts design.

Figure 2: The final pot skirt prototypes assembled on the channel stove.

In order to ascertain the optimal balance between the channel stove’s technical capability and usability, we designed a set of inexpensive pot skirts that integrate directly with the traditional stove. These pot skirts allow for varying sizes and number of pots and the use of traditional fuels. Due to the traditional channel cookstove’s very low heat transfer efficiency, pot skirts were found to be one of the most effective ways to improve this deficit, compared to other options considered. Pot skirts function by directing the hot gases, released during combustion, to pass directly along the sides of the pot. This results in higher flow temperatures and higher heat transfer efficiencies. An increase in heat transfer efficiency is optimal for users since it leads to decreased cooking time and smoke reduction. The pot skirts also absorb some of the convective heat released by the gases and radiate it back to the combustion zone to promote more efficient combustion.

Each pot skirt used in this study is constructed from 24-gauge thickness sheet metal but other thicknesses are also acceptable. It can be cut or stamped out of a single piece of metal, which decreases manufacturing costs. The two trapezoidal side panels are bent to lay against the sides of the cooking pot and force the hot air to circulate around the pot on all sides. The skirt also includes a wood covered handle, which allows for easy placement and adjustment. The pot skirts are designed to allow users to use any size of pot ranging from 20 to 32 cm, and allow for easy adjustment or temporary removal of the skirts.

Field-testing was performed to determine its acceptance and compatibility with the end users. This testing was conducted on fifty-four households in the small community of Locuto, located in the Tambogrande district of Peru, during the summer of 2015. Adoption rates are estimated to be 35%. We also tested the pot skirts at the biomass burn facility at Brigham Young University, using a channel stove that we created. Lab testing identified the skirts’ technical improvements: 25.8% increased thermal efficiency, 26.0% decreased fuel consumption, and 26.0% decreased time to boil. Water Boiling Tests performed in the lab proved the skirts’ effectiveness in decreasing boiling time by 30.2%, decreasing fuel usage by 26.1%, and increasing the efficiency by 35.9%. Fieldtesting revealed a high level of user acceptance, with 73% of the participants using them regularly and over 30% of the participants willing to pay more than 5 PEN for the skirts. Furthermore, in addition to improving the technical performance of the stove, the pot skirts minimally disrupt the user’s customary way of cooking. Although these technical improvements are less than other improved cookstoves on the market, the higher levels of usability and adoption are likely to lead to a greater overall impact. These results illustrate that greater impact can be attained through achieving a balance between the technical capabilities and usability of improved cookstove design. Future areas of work include altering the design to work better with smaller pots, especially those that are shorter in height. Additionally, we would consider modifying the handles so that they are not as hot during operation in order to further enhance the usability of the pot skirts.

The results of this research were submitted to the 2015 ASME IDETC/CIE conference in a paper titled, “Preserving the Usability of a Peruvian Cookstove: A More Balanced Approach to Improved Cookstove Design”. In December of 2015, we also submitted our research to the Development Engineering Journal, in a paper titled, “Balancing Technical and User Objectives in the Redesign of a Peruvian Cookstove”.

1Bordereau, S. (1987). Biomass stoves. Arlington, Va., USA: Volunteers in Technical Assistance.

2V. Ramanathan, G. Carmichael, Global and regional climate changes due to black carbon, Nature

geoscience 1 (4) (2008) 221–227.