Steven Stanley and Bradley C. Bundy, Department of Chemical Engineering

The genetic code, once mainly restricted to the 20 canonical amino acids, has been expanded to include many unnatural amino acids (UAAs). These new amino acids grant novel chemistries to proteins, unlocking functionalities that could be used in vaccine development and medical diagnosis methods. Unfortunately, current techniques allow for the insertion of only a single UAA into a protein1, greatly limiting the range of chemistries offered by UAAs. Dr. Bundy’s lab has been engaged in research to overcome the barriers to the simultaneous insertion of multiple UAAs through cell-free (i.e. in vitro) protein synthesis methods. tRNA synthetase is a protein that charges tRNA molecules with their corresponding amino acid. In order to charge tRNA with UAAs, synthetase proteins corresponding to the UAA must be synthesized. Synthetase sets specific to many of the UAAs have limited solubility in water, making it difficult to incorporate these synthetases into the labs cell-free protein synthesis methods. My project sought to aid the lab in overcoming this barrier of limited solubility and optimize the synthesis and purification of three sets of tRNA synthetase each abbreviated MbRS, PhRS, and ScRS.

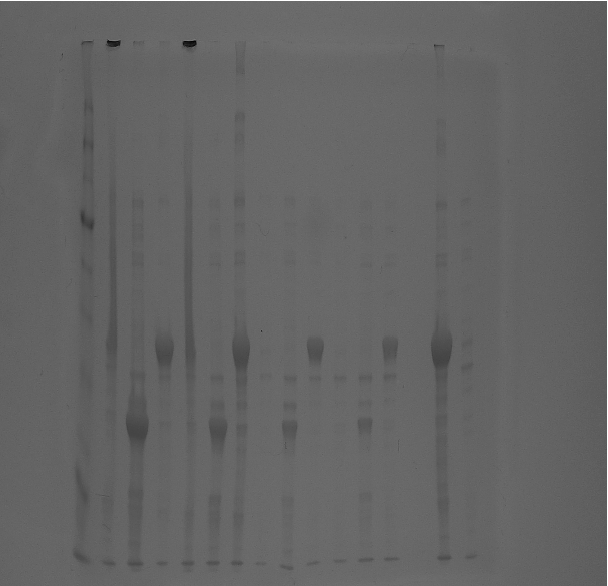

Many factors can influence the growth and solubility of the synthetase protein including salinity, pH, and time of induced growth. Because cell growth is an integral step in producing synthetase, the effects of cell growth media on synthetase solubility were tested first. Dr. Bundy’s lab utilizes two types of cell growth media, LB Broth (LB) and Terrific Broth (TB), which were tested by producing each synthetase in each media type. Each synthetase was grown at 30 °C in BL21 Star (DE3) chemically competent E. coli and synthetase growth was induced at an optical density of around 0.66 using 40uM IPTG. The cells were harvested a day later at an average optical density of 4.5 for LB cultures and 12.9 for TB cultures. The cells were then centrifuged at 6000g for 15 minutes, re-suspended in 2mL imidazole solution per gram of cells, and then lysed with a sonicator. Lysed cells were then centrifuged at 30,000 rpm to separate the water-soluble fraction from the cell wall and the heavy, insoluble synthetase aggregates. But before centrifuging the sample, a portion of the lysed cell solution was saved for use as a comparison of the amount of insoluble synthetase to the soluble synthetase fractions. The soluble and insoluble fractions were analyzed using a protein electrophoresis gel (see Figure 1) and ImageJ software to confirm synthetase over-amplification and compare the intensity of the soluble and insoluble bands for each media type.

The software analyzed the peak intensity for each synthetase band on the gel and integrated this intensity over the selected band region. An analysis was not performed on MbRS due to the fact that the MbRS smeared the gel lanes (see Figure 1). Taking ratios of the PhRS soluble and insoluble fraction band intensities for each media it was found that the ratio of soluble TB to insoluble TB band intensities was 0.24 and that the ratio of LB soluble to LB insoluble band intensities was 0.28. This showed that PhRS grown in LB media saw fewer solubility losses than PhRS grown in TB. A similar analysis was done for ScRS, however the results showed nearly equal solubility losses for ScRS grown in LB and TB media. These results suggest an increased solubility of PhRS when grown in LB media and no significant solubility difference for ScRS grown in either media.

After learning the effects of growth media, experiments were performed to analyze the effects of salt type and concentration on the solubility of MbRS. This was done by growing MbRS in TB media, lysing the cells, and isolating the soluble MbRS using fast protein column liquid chromatography. The purified fractions of MbRS were then dialyzed in different solutions of salt. Unfortunately, none of the salts tested proved successful in promoting the solubility of MbRS to the level necessary for cell-free protein synthesis.

The needs of the lab evolve quickly and I was asked to change the direction of my efforts. I was therefore unable to complete tests on the effects of salt concentration and time of incubation on synthetase solubility. My results show that PhRS grown in LB media has fewer solubility losses than PhRS grown in TB media and that ScRS can be grown in either media type with equal solubility losses.

Acknowledgements

I would like to thank Dr. Bundy for making this study possible. I would also like to thank Dr. Mark Smith and Ph.D. candidate, Amin Salehi, for their guidance and help on this project. Figure 1: Protein electrophoresis gel with bands displaying overamplification. Well contents from left to right: Protein ladder, MbRS in TB (Insoluble Fraction), PhRS in TB (Insoluble Fraction), ScRS in TB (Insoluble Fraction), MbRS in LB (Insoluble Fraction), PhRS in LB (Insoluble Fraction), ScRS in LB (Insoluble Fraction), MbRS in TB (Soluble Fraction), PhRS in TB (Soluble Fraction), ScRS in TB (Soluble Fraction), MbRS in LB (Soluble Fraction), PhRS in LB (Soluble Fraction), ScRS in LB (Soluble Fraction), final 2 wells are repeats of sample wells that acquired defects.

Figure 1: Protein electrophoresis gel with bands displaying overamplification. Well contents from left to right: Protein ladder,

MbRS in TB (Insoluble Fraction), PhRS in TB (Insoluble Fraction), ScRS in TB (Insoluble Fraction), MbRS in LB (Insoluble

Fraction), PhRS in LB (Insoluble Fraction), ScRS in LB (Insoluble Fraction), MbRS in TB (Soluble Fraction), PhRS in TB

(Soluble Fraction), ScRS in TB (Soluble Fraction), MbRS in LB (Soluble Fraction), PhRS in LB (Soluble Fraction), ScRS in LB

(Soluble Fraction), final 2 wells are repeats of sample wells that acquired defects.

1Passioura, T., & Suga, H. (2014). Reprogramming the genetic code in vitro. Trends in Biomedical Sciences, 39(9), 400-408.