Richard Vanfleet, Physics and Astronomy

This Mentored Environment Grant (MEG) proposed to explore Carbon Nanotube Templated Microfabrication (CNT-M) approaches that used metal as the infiltration material. We proposed to focus on two specific metal systems; traditionally electrodeposited metals such as nickel and high atomic number metals like tungsten which in many cases cannot be electroplated. Our two objectives were:

- Develop metal electroplating materials and processes for uniform CNT framework infiltration.

- Develop metal Atomic Layer Deposition (ALD) materials and processes for uniform CNT framework infiltration.

Description of the results/findings of the project

The Nickel electroplating process has proved very successful. However, the tungsten ALD process has not progressed as far as hoped. One paper has been submitted and accepted with a second planned and the experiments are under design. The paper has been accepted for publication in the Journal of Micro Electrical Mechanical Systems (JMEMS) and is titled “High-Aspect-Ratio Metal Microfabrication by Nickel Electroplating of Patterned Carbon Nanotube Forests” with authors Lawrence K. Barrett, Dallin J. Barton, Steven G. Noyce, David D. Allred, Richard R. Vanfleet, and Robert C. Davis. This work has also been important for a collaboration with General Electric Global Research that garnered $37k in seed project funding from GE in 2014 and is likely to receive additional GE funding in 2015. A larger NIH joint proposal with GE and Brown University is proposed in 2015 using the CNT-M process with metal infiltration for neural implant probes. This work and one of the student working on the project were involved in a summer collaboration with researchers at the University of Alabama. This work has also been important for a proposed Physics-Chemistry collaboration on CNT based capacitors and as a potential filter media for possible startup company.

Nickle Electroplating.

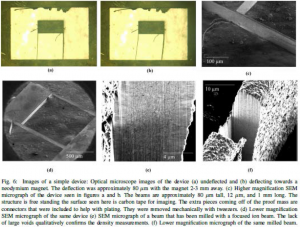

Figure 6 below is an example of the electroplating results and is one of the figures from the JMEMS paper that has been submitted and accepted but will publish in 2015. We have shown consistent reproducible results with the following key steps:

- Short carbon coating of the CNT forest to link adjacent nanotubes and make it sufficiently robust for liquid processing.

- 30 min ozone treatment to make the carbon CNT structure hydrophilic.

- Nickel chloride as the bath solution at 40º C.

- 30 min presoak in the bath.

- Pulse coating with a 3 ms on and 27 ms off cycle.

Preliminary materials properties show a material that is nearly solid (86% the density of bulk nickel with much of the shortfall being carbon) but is more compliant (young’s modulus about ¼ of bulk) while having similar strength to bulk nickel. These interesting properties may be directly due to the presence of nanotubes in the structure or indirectly related to nanotubes by their impacting the grain structure of the resulting material. Further microstructural studies by TEM and FIB/SEM are planned. Additional proposed studies for optimization are varying ozone treatment, on/off duty cycle in the electroplating, and post deposition anneals to modify the grain structure.

Tungsten ALD

The tungsten ALD work required significant equipment work and proved slow. We made modifications to our metal carbonyl deposition system, to the room, toxic gas abatement systems and gas sensors. Due to delays in room modifications and safety considerations we initially started with co-flows of tungsten hexafluoride and hydrogen (not disilane). These proved unsuitable and typically coated on the outside of the nanotube structure. The system and safety considerations are largely in place and we hope to continue this work with a full ALD cycling process.

Academic Objectives

We expect students to do good research that will form the core of their senior thesis, local, regional, and national presentations, and publications in scientific journals. We planned on submitting a manuscript for publication within a year of starting the project. We expected that students would present their work at the APS four corners meeting in October, at the college of physical and mathematical sciences sponsored research conference in the spring and/or at an appropriate national conferences venue. Based on past experience, we anticipated that patents will result from this effort and contribute to the CNT-M patent portfolio of the University.

Three senior thesis from work on this project were completed in 2014 and one more will finish in 2015. One paper was submitted and accepted and a second is being planned. Three presentation was made at the CPMS Student research conference, one at the APS four corners section meeting, and four presentations were made at national AVS meetings. No new patents have been submitted on the metal work but one had been submitted just prior to the MEG award.

Mentoring Environment

Overall the mentored environment operated as desired. We have a large active group of students that meet together weekly during the Fall and Winter semesters. This is the “group” meeting that was proposed where students present practice talks and research summaries to all the students and faculty in the group. Project meetings are smaller groups where the specifics of project results are discussed and plans are made. We had our good time and our bad times in implementing the project meetings on this project. Clearly in our mind some of the slowness and delays can and should be attributed to our failings in project oversight associated with project meetings and getting sufficient direction to students.

Students who participated in the project

As proposed we directly funded two students and involved two others through other means. Involvement through other means could be volunteer work, work for credit, internal department funding, or primary support through other related funded projects.

- Lawrence Barrett – Senior thesis (2014), lead student on the JMEMS paper (2014), AVS presentation (2013). Coauthor AVS presentation (2014).

- Dallin Barton – Direct project support, Senior thesis (expected 2015), co-author on JMEMS paper, co-author on AVS presentations (2013, 2014), CPMS SRC presentation (2014), 4corners APS presentation (2014), summer REU collaborating with Susan Burkett at the University of Alabama.

- Colin Brown – Direct project support, Senior thesis (2014), AVS presentation (2013)

- Jason Anderson – Senior thesis (2014), co-author AVS presentation (2013), CPMS SRC presentations (2013, 2014)

How budget was spent

Approximately $9k of the budget will have been spent on direct student support. This is less than had been anticipated due to success in students getting departmental awards and higher costs in other areas. $9k was spent on supplies and $2k on TEM/SEM time. These were about double what had been proposed. These funds ended up being spent over two years instead of one. While we were able to find financial support for students through other means we had to draw on MEG funds for supplies and characterization cost for a longer time and thus higher cost.

Papers and presentations:

Lawrence K. Barrett, Dallin J. Barton, Steven G. Noyce, David D. Allred, Richard R. Vanfleet, and Robert C. Davis, “High-Aspect-Ratio Metal Microfabrication by Nickel Electroplating of Patterned Carbon Nanotube Forests”, accepted December 2014, JMEMS

AVS 2013, Long beach CA.

- L. BARRETT, D. BARTON, R.C. DAVIS, R.R. VANFLEET, D.D. ALLRED, “Fabrication of 3D Nickel Microstructures by Pulsed Electrodeposition on Carbon Coated Carbon Nanotubes”

- D.D. ALLRED, R.R. VANFLEET, J.K. ANDERSON, C. BROWN, R.S. HANSEN, D. MCKENNA, R.C. DAVIS, “Preparation and Characterization of CVD & ALD Tungsten & Molybdenum Thin Films for CNT-M Metallic Microstructures”

AVS 2014, Baltimore MD.

- R.C. DAVIS, L. BARRETT, D. BARTON, R.R. VANFLEET, D.D. ALLRED, “High Aspect Ratio Magnetic MEMS Fabricated using Carbon Nanotube Templated Microfabrication”

- R.R. VANFLEET, L. BARRETT, J. ROWLEY, K. HINTON, R.C.DAVIS, D.D. ALLRED, “Ozone Pretreatment’s Effect on Infiltration of Carbon Nanotube Forests”

CPMS SRC 2013, BYU

- Jason Anderson, David Allred, “Tungsten Coating Nanostructures Using Atomic Layer Deposition”

CPMS SRC 2014, BYU

- Dallin Barton, Richard Vanfleet, “Nickel Infiltrating Carbon Nanotubes”

- Jason Anderson, David Allred, “The Fabrication of Microelectromechanical Systems (MEMS)”

APS 4corners section 2014, Orem Utah

- Dallin Barton, Lawrence Barrett, Steven Noyce, David Allred, Richard Vanfleet, Robert Davis, “High-Aspect-Ratio Metal Microfabrication by Nickel Electroplating of Patterned Carbon Nanotube Forests”