Samikshya Subedi and Dr. David Fullwood, Department of Mechanical Engineering

Purpose of the Study

The purpose of this study was to understand and predict the role of the triple junction on crack initiation in polycrystals. I intended to study dislocation density fields and local elastic strain around the triple junction area in a metal and understand how these factors facilitate crack nucleation and propagation.

I was able to conduct experiments, get sensible data and reach a reasonable conclusion from my data. I expected to measure dislocation density values at triple junction points – a point where three grains meet. I was not able to do this at a triple junction point but at grain boundaries, lines which separate two grains. Grain boundaries are often sites of nuclear crack and propagation. To validate this point, in this paper, I compared those defects or irregularities called dislocation density values in grains and grain boundaries. Wherever these values are higher is often the site from where breaking of metal starts.

I presented part of this work as a poster presentation in TMS conference at San Diego, California.

Procedures

The instrument shown in Figure 1b is an in-situ tensile stage that was used to apply strain in the material. I designed and built this stage so that it can fit into the microscope as shown in figure 1b. The knob shown at farthest left end in figure 1b was used to apply strain into the material. The percentage of strain was calculated by the number of times the knob was rotated.

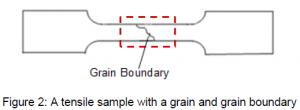

Sample shown in figure 2 was cut using the wire EDM (Electric Discharge Machine). Even though grains and grain boundaries could be seen with the naked eye, one of the biggest problems I had to face was how to cut the sample in the exact right location to isolate the two grains I needed to investigate. Cutting just a few microns off could produce a completely undesired sample, meaning I had to cut samples again and again for hours to get exactly what I was looking for. Also these samples have to be polished before their usability can be determined. Many times I would get higher than ideal dislocation density value and had to re-polish to get this value down to the lower number which was very tedious. After trying several different methods to obtain the necessary high quality surface using Silicon Carbide sand paper, diamond suspension, and colloidal silica for polishing I was ultimately able to improve polishing methods. And this allowed me to demonstrate the feasibility of reaching the dislocation density resolution limit in the Fe-Si material.

Conclusion

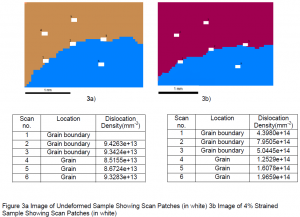

In Figure 3a, there is uniform dislocation density between the scan areas at the grain boundary and those in the grain. This shows that the material is well annealed and that there is little remaining deformation at the grain boundary. Whereas in Figure 3b, the strained sample, there is a significant change in dislocation density at the grain boundary, which demonstrates how dislocations build up more at the grain boundary than in the grain itself. Therefore, grain boundaries are more prone to cracks and failure.

The orca grant proved really very helpful on conducting this research. I sincerely want to thank Dr. Fullwood who helped me a lot throughout the research and thank my sponsors who gave me this wonderful opportunity to do this research and to learn and grow. I was able to accomplish most of my goal. There could be done some further research for example at triple junction instead of at grain boundary and validate this result more. But I am happy and satisfied with what I have accomplished.

References

- Shen, Z., Wagoner, R. H., Clark, W. A. T., Dislocation pile-up and grain boundary interactions in 304 stainless steel. Scripta Metall., 1986. 20: p. 921.

- Peirce, D., Asaro, R. J., Needleman, A., Materials rate dependence and localized deformation in crystalline solids. Acta metall., 1983. 31: p. 1951-1976.

- Lee, M.G., Lim, H., Adams, B. L., Hirth, J.P., Wagoner, R. H.,, A dislocation density-based single crystal constitutive equation. International Journal of Plasticity, 2010. 26: p. 925-938.

- Armstrong, R.W., Advances in Materials Research, ed. R.F. Bunshah. Vol. 4. 1971, NY: Wiley-Interscience.