Jason Kyle Anderson and Dr. David Allred, Department of Physics and Astronomy

Introduction:

Traditional micro fabrication processes are confined to a small subset of possible materials due to limitations on etching and are confined to low aspect ratio fabrication due to limits in both etching and stability of thicker film deposition processes. Carbon Nanotube Templated Microfabrication (CNT-M) technology has introduced a dramatically different approach to micro fabrication that fabricates without significant etching processes and achieves thick features with the equivalent of thin stable depositions. This is achieved by forming the desired structure in carbon nanotubes and then filling, or infiltrating, that structure with the material of choice. Optimal materials infiltration for CNT-M should be limited not by mass transfer into the structure, but by sticking of reacting species to the carbon nanotubes. This technology has been developed at BYU using materials like silicon and carbon; however, a suitable metals process has not yet been found. Micro fabrication of metals is sought after for their higher density, and improved electrical and mechanical properties as compared to silicon and other traditional micro fabrication materials. I began the project to develop atomic layer deposition (ALD) of W (Tungsten) using atomic H (Hydrogen) as the agent for abstracting the nonmetal atoms such as C, O or F that act as ligands for the gaseous form of W used to bring the W into the deposition. This has a high likelihood of success for CNT-M application. This success stems from the ability to decouple the mass transfer of the metal from the deposition on the nanotubes. If these processes are successful, a whole new range of micro fabricated devices such as high sensitivity inertial sensors, x-ray collimators, and high strength micro sieve filters will be enabled. All three of these potential applications have commercialization routes either through interest from companies or forming of a company.

Methodology:

Our technique for ALD was to use WF6 as a deposition layer on the carbon nanostructures. Because of the fluorine this is a self-limiting deposition, meaning the molecules won’t stick together and we will achieve a limited deposition, preventing blocking off of infiltration passages. This is important in order to achieve a uniform deposition throughout the entire structure, rather than clumping together on the edges. We then flowed a Hydrogen plasma through the sample chamber, causing the H atoms to remove F (Fluorine) atoms from the WF6, leaving a thin layer of W deposited. The cycle was repeated many times to achieve W deposition.

Our main challenge in completing this project was re-configuring an existing Chemical Vapor Deposition (CVD) system to allow for Atomic Layer Deposition (ALD) techniques. We first had to hook up additional gas lines into the system to introduce WF6 and we had to install a microwave generator and an antenna to create the H plasma. We also installed filters and sensors for HF, a toxic byproduct of the chemical reaction, as well as leak proofing the cabinet to prevent escape of dangerous gasses. The deposition was performed at around 230° C and flow rates were calibrated at 30 sccm.

Results:

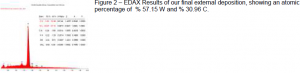

The first runs of the system were done for 10 cycles of WF6 and H, with the sample being exposed to both gasses for alternating cycles of 30 seconds. The plasma was not used, but rather molecular H. This deposition was limited to an atomic composition of % 94 Carbon and % 1.4 W. Consequent runs were changed to be 5 second intervals for each gas and the use of Hydrogen plasma as the reacting agent. These yielded samples composed of % 62.48 C and % 22.04 W. Eventually another process was added to sample preparation, ozone treatment. This process yielded samples with a composition of % 30.96 C and % 57.15 (seen in figures 1 and 2). The additional percentages were attributed to silicon from the Si substrate, Fluorine from WF6, and Oxygen. The deposition within the structure was measured to be % 69.97 C and % 15.16 W.

Discussion:

The process was gradually improved to produce better percentages of W in the final samples. The main contributing factors to deposition appear to be use of the H plasma, containing more energy than the H gas to remove F from the sample, and ozone treatment of the samples, creating more attachment sites on the carbon nanotubes for the WF6 to deposit. The discrepancy between outside and inside measurements of the final samples shows in a drop of almost % 45 W. Thus, while the process has been established and improved, there is still not uniform deposition in the samples.

Conclusion:

We were able to reconfigure a CVD system and create a process for ALD of W onto carbon nanotubes. This process was refined to create carbon nanotube templated W structure composed of almost % 60 W on the outer edges of the structure; however this did not extend inside the structure. There are still many factors to be refined in this process to achieve more uniform deposition throughout the structure. We will continue to experiment with flow rates, exposure times, cycle numbers, and temperature.